What is a Surface Mount Circuit Board?

Introduction to surface mount circuit board

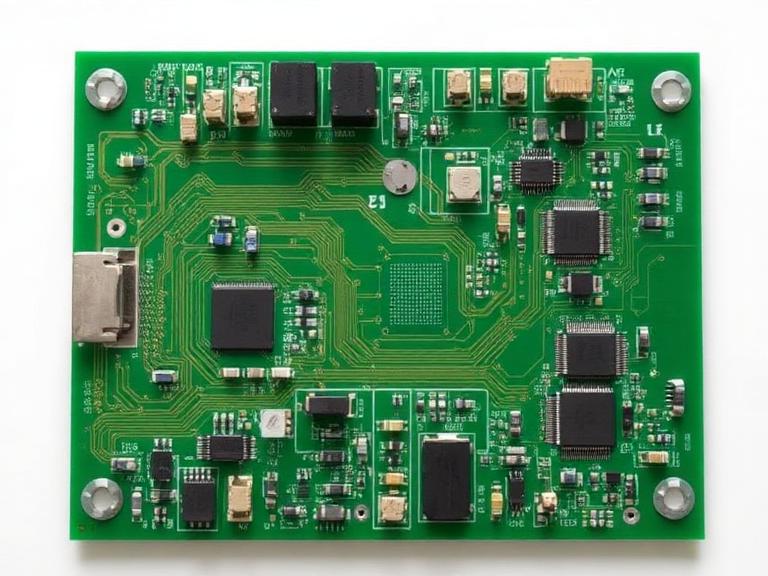

In modern electronics, the term surface mount circuit board appears on datasheets, design guides and supplier catalogs alike. As devices shrink and functionality grows, engineers increasingly choose surface mount circuit boards (SMCBs) for consumer electronics, industrial controls, medical devices and aerospace systems. This guide explains precisely what a surface mount circuit board is, how surface mount technology (SMT) works, and practical advice for design, manufacture and selection of a reliable production partner.

Table of Contents

- Introduction

- Definition: What is a Surface Mount Circuit Board?

- SMT vs Through-Hole: Key Differences

- Common Surface Mount Components

- Design & PCB Layout Considerations

- Manufacturing: How Surface Mount Assembly Works

- Testing, Inspection & Quality Control

- Advantages & Limitations

- Maintenance & Repair Tips

- Choosing a Manufacturer — Wintech

- Summary Comparison Table

- Frequently Asked Questions (FAQ)

- References

Definition: What is a Surface Mount Circuit Board?

A surface mount circuit board is a printed circuit board (PCB) that uses surface mount technology to attach electronic components directly to the surface of the board. Unlike through-hole assembly, surface mount components are soldered to exposed pads on the PCB surface, enabling higher component density, smaller board size and improved electrical performance.

Core concept

With a surface mount circuit board, components such as resistors, capacitors, ICs and LEDs are placed and soldered on the board's surface via SMD pads and solder paste. This approach is fundamental to automated assembly lines and is the backbone of modern electronics manufacturing.

SMT vs Through-Hole: Key Differences

Understanding the difference helps you choose the right construction for your product.

Size & density

Surface mount circuit boards typically allow much higher component density than through-hole boards because components sit flat and occupy less vertical space. This enables slimmer devices and more complex circuits on a single board.

Manufacturing & cost

SMT favors automated pick-and-place and reflow soldering, reducing labor costs at scale. Through-hole may still be used for mechanical strength or specialized connectors, but generally it is more labor-intensive and expensive for high-volume runs.

Performance & reliability

Surface mount circuit boards often provide better high-frequency performance and lower parasitics (inductance and capacitance) because of shorter lead paths. However, through-hole connections can be more robust for shock and vibration in some environments.

Common Surface Mount Components

Surface mount components (SMDs) come in many packages. Here are the most common:

- Passive SMDs: resistors (0603, 0402…), capacitors, inductors.

- IC packages: QFN, QFP, BGA, SOIC.

- Discrete semiconductors: SOT-23 transistors and diodes.

- Connectors & LEDs: low-profile board-mount options.

- Power modules: MOSFETs and power ICs in thermal-friendly packages.

Package selection & trade-offs

Choose package types based on thermal demands, board density and reworkability. For example, BGAs save space but require X-ray inspection for solder joint verification.

Design & PCB Layout Considerations for Surface Mount Circuit Boards

A successful surface mount circuit board starts in the PCB CAD tool. Proper footprint, pad geometry, thermal relief and routing strategies are essential.

Footprint and land pattern

Use IPC-compliant footprints for SMDs so components align with pick-and-place tolerances. Accurate land patterns reduce solder bridging and tombstoning.

Pad & stencil design

Design solder paste stencils to deposit consistent paste volumes. For BGAs, consider segmented paste patterns to control outgassing and avoid voids.

Thermal management

Power devices require thermal vias, copper pours and heat sinks. On the surface mount circuit board, thermal design influences both reliability and performance.

Routing & impedance control

For high-speed signals, control trace impedance, maintain differential pair spacing, and manage return paths to reduce EMI. Surface mount circuit boards enable shorter trace lengths and cleaner signal integrity when designed correctly.

Manufacturing: How Surface Mount Assembly Works

The typical process for making a surface mount circuit board includes PCB fabrication, solder paste application, pick-and-place, reflow soldering, cleaning (if needed) and inspection/testing.

1. PCB fabrication

Fabricate the PCB to spec: layer stack-up, surface finish (ENIG, HASL, OSP), solder mask and silkscreen. The board must meet tolerances for pad flatness and planarity to suit SMT.

2. Solder paste application

Stencil printers deposit solder paste precisely onto SMD pads. Consistent paste deposition is vital for good solder joints after reflow.

3. Pick-and-place

High-speed pick-and-place machines place components accurately (±50 µm to ±100 µm). Machines use feeders, vision systems and fiducials on the board for alignment.

4. Reflow soldering

Reflow ovens pass boards through temperature zones to melt the solder paste and form metallurgical joints. Profile tuning ensures adequate wetting without thermal damage.

5. Cleaning & flux removal

Some assemblies require cleaning to remove flux residues; no-clean processes are common but must be verified for reliability in the target environment.

6. Inspection & rework

Automated Optical Inspection (AOI), X-ray for BGAs, and manual rework stations address defects. Reflow defects like tombstoning, bridging or misalignment must be minimized.

Testing, Inspection & Quality Control

A surface mount circuit board undergoes rigorous validation: continuity checks, in-circuit testing (ICT), functional test, and environmental reliability tests.

Key methods

- AOI (Automated Optical Inspection): detects visible solder issues and missing components.

- X-ray inspection: used for hidden joints such as BGAs.

- ICT / Flying probe: checks for shorts, opens and component values.

- Functional testing: validates end-to-end circuit performance.

- Environmental testing: thermal cycling and vibration for reliability.

Advantages & Limitations of Surface Mount Circuit Boards

Advantages

- Higher component density and smaller board footprint.

- Reduced parasitic effects for better high-frequency performance.

- Faster automated assembly and lower per-unit labor costs at volume.

- Improved thermal paths by using copper pours and thermal vias.

Limitations

- Some surface mount components are harder to rework or test manually (e.g., BGAs).

- Initial NPI setup (stencil, feeders, profiles) can add time for prototypes.

- Mechanical stress tolerance can be lower than reinforced through-hole for certain connectors.

Maintenance & Repair Tips for Surface Mount Circuit Boards

Even with high-quality assembly, boards require good practices to extend life and ease repair.

- Document the BOM and PCB revisions to track component sources and footprints.

- Use proper ESD handling procedures during repair and testing.

- Employ hot-air rework stations or reflow ovens for SMD repairs—avoid excessive mechanical force.

- For BGAs, consult X-ray inspection before reballing or rework to confirm internal joint issues.

Choosing a Manufacturer for Surface Mount Circuit Boards — Wintech

When you need a reliable partner for surface mount circuit board production, choose an experienced turnkey provider. Wintech is a full-turnkey service provider offering high-mix, low-to-mid volume electronics manufacturing and custom material solutions.

Why Wintech for your surface mount circuit board needs

Wintech supports the entire product lifecycle—from PCB design and layout to prototype, PCBA SMT assembly, and full turnkey production. Their strengths align with what teams need to produce a robust surface mount circuit board:

- High-precision PCB design & layout tailored for SMT

- PCB manufacturing with controlled quality and surface finishes

- PCB assembly & PCBA SMT with pick-and-place and reflow capabilities

- Quick-turn fast PCB prototype assembly and NPI support

- Plastic molding, metal precision machining, enclosures and full system integration

Services Wintech provides

Wintech's service stack is ideal for projects that require a high level of integration and quality control:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

- Backplanes & Sever Chasis

- Cable Harness & Assembly

- Cabinet & Panel PLC Wiring

Pro tip: When sourcing a surface mount circuit board, ask your manufacturer about design for manufacturability (DFM) checks, solder finish options (ENIG vs HASL), and their defect rates (DPMO). Wintech routinely performs DFM and pre-production reviews to minimize surprises during ramp.

Summary Comparison Table

| Topic | Surface Mount Circuit Board (SMCB) | Practical note |

|---|---|---|

| Primary use | High-density electronic assemblies | Consumer, industrial, medical, aerospace |

| Manufacturing | Automated pick-and-place + reflow | Faster at volume; requires initial setup |

| Size | Smaller footprints possible | Enables compact product designs |

| Testability | AOI, X-ray, ICT required for hidden joints | Design test points when possible |

| Rework | Feasible with hot-air and IR rework | Some packages are difficult (BGA) |

Frequently Asked Questions (FAQ)

1. What exactly is a surface mount circuit board?

A surface mount circuit board is a PCB assembled using surface mount technology where components are mounted on the board surface instead of inserted through holes.

2. Why choose a surface mount circuit board over through-hole?

Advantages include smaller size, higher component density, better high-frequency performance and lower per-unit labor cost at scale.

3. Are surface mount boards harder to repair?

Some components (like BGAs) require specialized equipment for repair, but most SMDs are repairable with hot-air rework and a practiced technician.

4. Can Wintech produce prototypes and scale to mass production?

Yes — Wintech specializes in quick-turn prototypes, NPI and scale-up for low-to-mid volume production and mass runs with turnkey integration.

5. What should I provide to a manufacturer to get a quote for a surface mount circuit board?

Provide Gerber files, BOM (with preferred manufacturers/parts), assembly drawings, target volumes, and any special requirements (conformal coating, impedance control, etc.).

References

- IPC Standards for PCB Design and Assembly (IPC-2221, IPC-A-610)

- SMT and PCB Manufacturing Whitepapers (2023–2025 industry updates)