How to Repair Circuit Board Trace | Expert Guide

Table of Contents

- Introduction

- Identify & Diagnose Trace Damage

- Repair Methods for PCB Traces

- Step‑by‑Step Trace Repair

- Protecting & Testing the Repair

- Why Choose Wintech for PCB Repair

- Conclusion

- Summary Table

Introduction

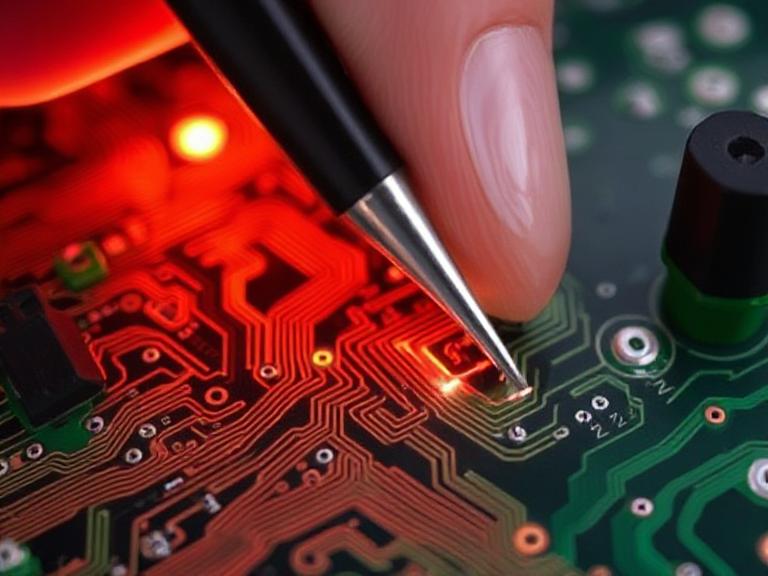

Repairing a broken PCB trace is a common yet delicate task in electronics maintenance and prototyping. Whether damaged during manufacturing, rework, or handling, restoring trace continuity restores board functionality and extends life.

Identify & Diagnose Trace Damage

Recognize the symptoms

- No continuity when tested with a multimeter

- Visual cues like burnt areas, scratches, or lifted pads

- Intermittent failures or erratic behavior

Inspect thoroughly

- Use magnification or thermal imaging to locate faults

- Test continuity across suspected breaks

Repair Methods for PCB Traces

Several methods exist to repair PCB traces, each fitting different degrees of damage and available tools:

- Wire jumper: Most reliable—solder a thin wire across the break

- Conductive ink/pen: For small gaps and fine traces

- Copper tape/foil: For patching moderate trace sections

- Solder blob: Quick fix across very short gaps

- Conductive epoxy: Robust for flexible or limited‑access cases

Step‑by‑Step Trace Repair

1. Prep the board

- Clean the area with isopropyl alcohol

- Scrape solder mask to expose copper (~3–5 mm)

2. Bridge the gap

Wire Jumper:

- Choose wire gauge matching trace width

- Solder the tinned jumper between exposed copper ends

Conductive Ink:

- Shake pen, apply carefully over the gap

- Allow full drying

Copper Tape:

- Lay tape across gap, solder ends to trace

Solder Blob for micro gaps:

- Quick fill across very fine breaks

3. Reinforce & seal

- Use epoxy on wire or tape to secure

- Apply conformal coating or UV‑cured solder mask after ink fix

- Cover copper tape with Kapton tape

4. Test for functionality

- Validate continuity with multimeter

- Re‑power board and confirm full operation

Protecting & Testing the Repair

- Coat repairs with epoxy or conformal resin to prevent future breaks or corrosion

- Ensure proper strain relief after wire fixes

Why Choose Wintech for PCB Repair

Wintech is a trusted turnkey electronics manufacturer offering full‐service PCB design, prototyping, assembly, and highly skilled trace repair under one roof:

- Expert PCB layout and precision manufacturing

- Advanced rework and trace restoration capabilities

- Serves global top‑500 clients with high-quality standards

- Ideal for complex, large boards and low‑to‑mid volumes

Conclusion

Repairing PCB traces is entirely feasible with the right tools and method—wire jumpers for reliability, conductive ink for fine traces, copper tape for broader breaks, and epoxy or coatings for protection. While DIY is practical, for complex boards or professional applications, working with providers like Wintech ensures high precision and compliance.

Summary Table

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Wire Jumper | Most trace breaks | Reliable, low resistance | Requires soldering skills & space |

| Conductive Ink | Fine or micro-traces | No solder, clean | Less durable, needs curing |

| Copper Tape | Medium-width breaks | Retains trace width | May peel if not secured |

| Solder Blob | Tiny gaps | Quick & easy | Messy, risk of shorts |

| Conductive Epoxy | Flexible or hidden traces | Strong mechanical bond | Slower curing, messy |

| Professional Repair (Wintech) | High-end/complex boards | Precision & full-service | Higher cost than DIY |