How to Create a PCB Board: A Step-by-Step Guide for Beginners

Introduction

Creating a Printed Circuit Board (PCB) is an essential part of modern electronics. Whether you’re designing a simple device or working on a complex microelectronics system, PCBs are the backbone that enables electrical components to communicate with each other. In 2025, the demand for high-quality, efficient, and reliable PCBs has skyrocketed as industries such as telecommunications, automotive, and consumer electronics continue to evolve.

This article will walk you through the essential steps involved in creating a PCB board, from designing and manufacturing to assembly. We will also cover the necessary tools, materials, and common challenges encountered during the process. By the end of this guide, you will have a solid understanding of how PCBs are made and the factors that influence their creation.

What is a PCB (Printed Circuit Board)?

.jpg)

A Printed Circuit Board (PCB) is a flat board made from a non-conductive material, typically fiberglass or composite epoxy, onto which electrical components are mounted. These components are connected by conductive pathways, or "traces," which allow electricity to flow between them and perform their intended functions. PCBs are used in virtually every electronic device, from smartphones and computers to medical equipment and automotive systems.

Types of PCBs:

- Single-Sided PCBs: Components are placed on one side of the board.

- Double-Sided PCBs: Components are placed on both sides of the board.

- Multilayer PCBs: Multiple layers of conductive material are used to increase the board’s complexity and functionality.

- Flexible PCBs: These boards can be bent and shaped for applications requiring flexibility.

PCBs are classified based on the number of layers and the complexity of the circuits they carry, with multilayer boards being more common in advanced electronics.

The Process of Creating a PCB Board

Creating a PCB involves several key steps, from initial design to the final assembly. The following are the major stages involved in PCB creation:

Step 1: Design the PCB

The first and most crucial step in creating a PCB is the design phase. This is where you define the layout of your circuit and decide where each component will be placed.

Key Considerations in PCB Design:

- Schematic Diagram: A schematic diagram is a blueprint for the PCB, showing all the components and how they are electrically connected.

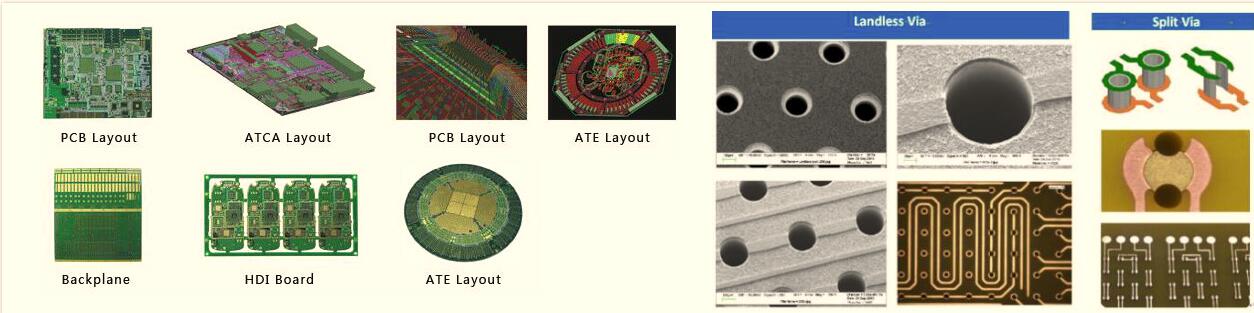

- PCB Layout: Once the schematic is complete, the layout begins. This involves positioning the components on the PCB and routing the conductive traces between them.

-

Software Tools: Various PCB design software tools help with both schematic capture and layout design. Popular tools include:

- AutoCAD: A CAD-based design software used for precise PCB designs.

- Eagle: A user-friendly PCB design tool with a robust library of components.

- KiCad: An open-source tool popular for both beginners and advanced users.

Tip: Ensure your PCB design adheres to industry standards like IPC-2221 for maximum compatibility and reliability.

Step 2: Fabricate the PCB

Once the PCB design is complete, the next step is the fabrication process, which involves transferring the design onto a physical board. Fabrication typically involves several key processes:

1. Printing the Design: The design is transferred onto a copper-clad board through a process called photolithography. The design is printed using a UV-sensitive film, which is then exposed to light to harden the circuit pattern.

2. Etching: After the design is printed, the board is etched using a chemical solution to remove the excess copper, leaving only the desired conductive traces.

3. Drilling Holes: If the PCB design requires through-hole components, small holes are drilled in the PCB for component leads to pass through.

4. Layering (for Multilayer PCBs): For multilayer PCBs, the fabrication process involves bonding multiple layers of copper and insulating material together.

5. Surface Finishing: A protective layer, such as HASL (Hot Air Solder Leveling) or ENIG (Electroless Nickel Immersion Gold), is applied to the copper traces to prevent oxidation and ensure the integrity of the PCB.

6. Quality Control: After the PCB is fabricated, it undergoes a thorough inspection process, including visual inspection and electrical testing, to ensure the design was accurately produced.

Step 3: Assemble the Components

The final step in PCB creation is component assembly, which involves placing the electronic components onto the board. This can be done through Surface Mount Technology (SMT) or Through-Hole Technology (THT), depending on the type of components and the design of the PCB.

Steps in PCB Assembly:

- Solder Paste Application: Solder paste is applied to the pads where the components will be mounted.

- Component Placement: Components are placed on the PCB using pick-and-place machines, which accurately position each part.

- Soldering: After placement, the PCB is passed through a soldering process, such as reflow soldering for SMT or wave soldering for THT.

- Inspection and Testing: The assembled PCB is inspected for quality and then tested to ensure it functions as intended.

Tools and Materials Required for PCB Manufacturing

Creating a PCB requires several tools and materials, both for design and manufacturing. Here are some of the most common tools used in PCB creation:

- PCB Design Software: Tools like AutoCAD, Eagle, and KiCad for creating the design.

- Copper-Clad Board: The base material for your PCB, usually made of fiberglass or composite epoxy.

- Etching Solution: Chemicals like ferric chloride or ammonium persulfate are used to etch away excess copper.

- Drilling Equipment: Machines for drilling holes in the PCB for component leads.

- Soldering Equipment: Soldering irons, reflow ovens, and wave soldering machines for component assembly.

- Testing Equipment: Equipment for performing electrical testing, such as multimeters and oscilloscopes.

Common Challenges in PCB Creation

Creating a PCB board involves technical precision, and several challenges may arise during the process:

- Design Errors: Mistakes during the design phase, such as incorrect trace widths or improper component placement, can lead to board failures.

- Manufacturing Defects: Errors in the fabrication process, such as poor etching or misalignment during drilling, can result in faulty boards.

- Component Placement Issues: Incorrect placement of components or insufficient soldering can lead to functionality problems in the final product.

- Cost and Time Management: PCB creation, especially for custom or advanced designs, can be costly and time-consuming. Efficient supply chain management and production planning are crucial to minimizing delays and staying within budget.

Wintech: A Leader in PCB Manufacturing and Assembly

At Wintech, we offer some of the most advanced manufacturing technologies in the electronics industry. With years of experience in designing, manufacturing, and assembling Printed Circuit Boards (PCBs), we cater to a wide range of industries, including telecommunications, automotive, medical, and consumer electronics.

Our Services:

- PCB Design & Layout: We provide professional design and layout services for your PCB needs, ensuring efficiency and reliability.

- PCB Manufacturing: Our state-of-the-art manufacturing capabilities ensure that your PCB is produced with precision and quality.

- PCB Assembly & PCBA SMT: We specialize in Surface Mount Technology (SMT) and Through-Hole Technology (THT) for component assembly.

- Quick Turn Fast PCB Prototype Assembly: Need prototypes fast? We offer quick-turn services to help you get your prototypes ready in no time.

- New Product Introduction (NPI): We support you from concept to production, helping you launch your product with ease.

Common FAQ About PCB Creation

1. How long does it take to create a PCB?

The timeline depends on the complexity of the PCB. Simple designs may take a few days, while more advanced designs, especially multilayer PCBs, can take a few weeks.

2. What materials are used to make a PCB?

PCBs are typically made of copper-clad boards, with a non-conductive base material such as fiberglass or composite epoxy.

3. What is the difference between SMT and THT in PCB assembly?

SMT (Surface Mount Technology) involves placing components directly onto the surface of the PCB, while THT (Through-Hole Technology) involves inserting