What Is Printed Circuit Board Assembly (PCBA)?

Table of Contents

- Introduction to Printed Circuit Board Assembly

- PCBA vs PCB: What's the Difference?

- The PCBA Manufacturing Process

- 1. Surface Mount Technology (SMT)

- 2. Through-Hole Technology (THT)

- 3. Inspection and Testing

- 4. Box Build and Final Assembly

- PCBA Manufacturing by Wintech

- Common Applications of PCBA

- Benefits of Using a PCBA Manufacturer

- Summary Table: Key Takeaways

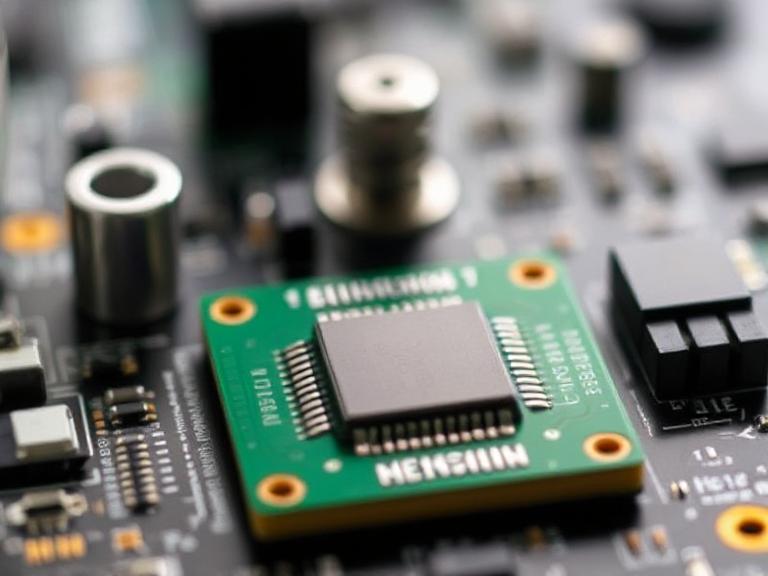

Introduction to Printed Circuit Board Assembly

Printed Circuit Board Assembly (PCBA) is the process of soldering or assembling electronic components onto a printed circuit board (PCB). The finished assembly allows the PCB to perform a specific electronic function, which could range from powering a smartphone to controlling an aerospace system.

Without PCBA, the bare PCB is just a non-functional substrate. The assembly process transforms it into the functional brain of electronic devices.

PCBA vs PCB: What's the Difference?

- PCB stands for Printed Circuit Board and refers to the board alone, without any electronic components.

- PCBA refers to the Printed Circuit Board Assembly — the finished board populated with components and ready for installation in a final product.

In short: PCB is the canvas, PCBA is the finished painting.

The PCBA Manufacturing Process

1. Surface Mount Technology (SMT)

SMT is the most common method used for mounting components onto a PCB.

- Solder paste is first applied to the board where components will be placed.

- Pick-and-place machines automatically place surface-mount components onto the board.

- Reflow soldering then melts the paste to fix the components in place.

2. Through-Hole Technology (THT)

This method is used for components with leads that must be inserted into holes drilled through the PCB.

- Best for components that require strong mechanical bonds.

- Often used in power electronics or larger industrial equipment.

3. Inspection and Testing

After assembly, rigorous inspection and testing ensure that the board functions as intended.

- Automated Optical Inspection (AOI)

- X-ray inspection for hidden solder joints

- Functional testing to simulate real-world operating conditions

4. Box Build and Final Assembly

This includes the integration of PCBA into an enclosure or product housing, adding displays, cables, and other accessories.

PCBA Manufacturing by Wintech

Wintech is a trusted name in the global electronics manufacturing services (EMS) industry, with 25+ years of experience in delivering high-quality PCBA and complete electronic manufacturing solutions.

Why Choose Wintech?- Vertically integrated services from design to final assembly

- Global clientele across North America, Europe, and Asia

- Support for low, medium, and high-volume manufacturing

- Cost reduction and faster time-to-market for clients

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

Wintech serves a variety of industries:

- Consumer electronics

- Telecom and communication

- Medical and healthcare devices

- Automotive electronics

- Industrial automation

- Aerospace and defense

Common Applications of PCBA

PCBA is used across virtually all electronic systems. Here are some key sectors:

- Consumer electronics: Smartphones, TVs, smartwatches

- Medical devices: Heart monitors, diagnostic machines

- Automotive: EV control systems, sensors, infotainment units

- Industrial: PLCs, control panels, automation units

- Telecom: Network routers, base stations, satellites

Benefits of Using a PCBA Manufacturer

Working with a professional PCBA manufacturer like Wintech provides several advantages:

- Expertise: Experienced teams that understand the full product life cycle

- Scalability: Support for low to high-volume production

- Quality Assurance: Certified quality controls and international standards

- Faster Time to Market: Integrated NPI and prototyping services

- Supply Chain Efficiency: Reliable component sourcing and logistics

Summary Table: Key Takeaways

| Aspect | Details |

|---|---|

| PCBA Definition | Printed Circuit Board Assembly - fully assembled board ready for installation |

| PCBA vs PCB | PCB is the raw board; PCBA is the completed and functional board |

| Main Processes | SMT, THT, inspection, box build |

| Key Industries | Consumer, telecom, medical, automotive, aerospace, industrial |

| Top Manufacturer | Wintech – 25+ years, global service, full EMS capabilities |

| Benefits of Outsourcing | Expertise, quality, scalability, cost efficiency, reduced time-to-market |

Conclusion: PCBA is the backbone of modern electronic functionality. Whether you’re building a medical device or launching a new smart gadget, choosing the right manufacturing partner is critical. With full-scale EMS capabilities, engineering expertise, and global client trust, Wintech stands out as a reliable and future-ready PCBA manufacturer.