How Much Does It Cost to Manufacture a PCB Board 2026?

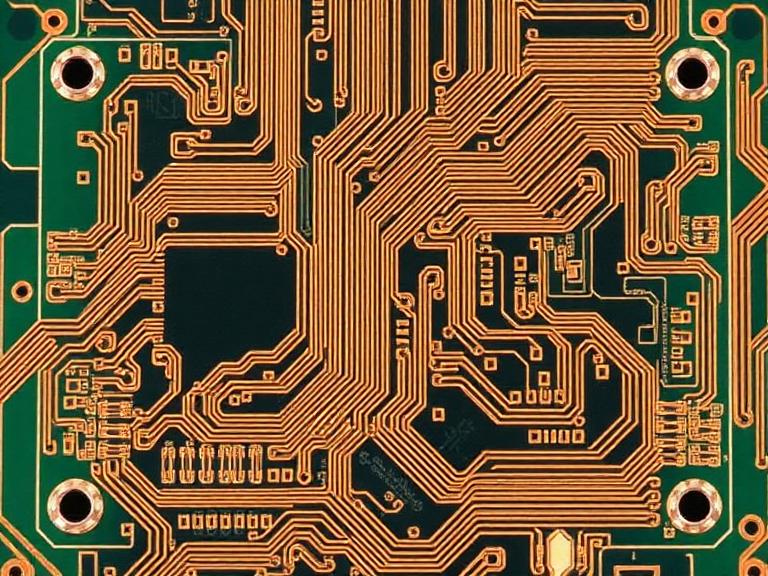

Navigating the electronics landscape in 2026 requires more than just innovative design; it demands a deep understanding of the financial variables that dictate the cost to manufacture a PCB board. As global supply chains stabilize and new high-frequency materials become the industry standard, the price of a printed circuit board is no longer a fixed metric. Instead, it is a dynamic calculation influenced by material science, layer complexity, and the rapid rise of Artificial Intelligence (AI) in manufacturing processes.

For hardware engineers, procurement officers, and startup founders, predicting the cost to manufacture a PCB board in 2026 involves balancing localized production incentives against the sheer volume-based savings of overseas fabrication. In this comprehensive guide, we break down the hard costs, hidden fees, and strategic maneuvers that will define your hardware budget this year.

- 1. The 2026 PCB Market Landscape: What’s Changed?

- 2. Primary Factors Affecting the Cost to Manufacture a PCB Board

- 3. Strategic Partner Spotlight: Wintech Solutions

- 4. Layer Count and Material Pricing Matrix

- 5. Regional Cost Comparison: China vs. North America vs. Europe

- 6. Prototyping vs. Mass Production Financials

- 7. Don't Ignore the Hidden Costs: Testing and NRE

- 8. 5 Strategies to Lower Your PCB Manufacturing Costs

- 9. Executive Summary Table

- 10. Frequently Asked Questions

- 11. References

1. The 2026 PCB Market Landscape: What’s Changed?

By early 2026, the cost to manufacture a PCB board has been heavily influenced by the mass adoption of High-Density Interconnect (HDI) technology. As consumer devices shrink and IoT sensors become more pervasive, the standard 2-layer FR4 board has moved into a niche "commodity" category. The real value—and the real expense—now lies in specialized substrates like Rogers for 5G/6G applications and heavy-copper boards for the booming Electric Vehicle (EV) sector.

Furthermore, ESG (Environmental, Social, and Governance) regulations have introduced "Green Fab" standards. Modern factories now incur higher overhead to maintain closed-loop water systems and additive manufacturing processes that reduce chemical waste. While these initiatives increase the baseline cost to manufacture a PCB board, they provide essential long-term stability and compliance for global brands.

2. Primary Factors Affecting the Cost to Manufacture a PCB Board

Material Selection (Substrate and Copper)

The foundation of any board is its substrate. Standard FR-4 remains the most cost-effective choice, but in 2026, copper prices have fluctuated by up to 35% year-over-year. High-TG (Glass Transition Temperature) materials, which prevent warping in high-heat environments like AI servers, now command a 15-25% premium over standard laminates. If your design requires flexible or rigid-flex materials (Polyimide), expect the cost to manufacture a PCB board to increase by 50% or more due to the complexity of the lamination process.

Board Dimensions and Panelization

The cost to manufacture a PCB board is fundamentally tied to how much of a standard production panel your design occupies. Designing a board at 10x8cm instead of 12x10cm can often save thousands of dollars on a medium-volume run by allowing more units to fit on a single panel. In 2026, smart panelization algorithms are now standard, but the physical area of the board remains the most linear cost driver.

Layer Count and Complexity

The jump from a 2-layer board to a 4-layer board generally increases the cost to manufacture a PCB board by 2.5 times. This is due to the additional lamination, drilling, and alignment steps required. For advanced 8-layer or 12-layer boards, the yield rate (the percentage of functional boards produced) becomes a major pricing factor. High-density designs with microvias or blind/buried vias can add a 40-100% premium to the fabrication cost.

3. Strategic Partner Spotlight: Wintech Solutions

Wintech: Your Trusted Turnkey Electronics Partner

Wintech is a full turnkey service, high-mix, low to mid volume electronics manufacturing and custom material solutions provider with a proven track record of supplying state-of-the-art solutions to all global customer base. We provide tailor made solutions for our customers, focusing on high level, high difficult, large size, and complex structure projects. Our expertise covers high precision PCB Layout, PCBAs and turnkey complete products full systems electronic contract manufacturing solutions, prototyping, low to mid volume, and mass production. Many of world's top 500 enterprises have cooperated with us for many years; Wintech is worth relying on.

Our Comprehensive Service Portfolio:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

- Backplanes & Sever Chasis

- Cable Harness & Assembly

- Cabinet & Panel PLC Wiring

- Electro-Mechanical Assembly

4. Layer Count and Material Pricing Matrix

When budgeting for 2026, it is helpful to use a standardized pricing matrix to estimate the cost to manufacture a PCB board. The following table reflects average global pricing for mid-volume orders (500–1000 units) for a standard 100mm x 100mm board size.

| PCB Type | Material (Substrate) | Estimated Cost per Unit (2026) | Complexity Rating |

|---|---|---|---|

| Single Layer | FR-4 Standard | $1.50 – $4.00 | Low |

| Double Layer | FR-4 Standard | $3.00 – $8.00 | Standard |

| 4-Layer | High-TG FR-4 | $12.00 – $25.00 | Moderate |

| 6-Layer | High-TG FR-4 | $25.00 – $55.00 | High |

| 10+ Layer (HDI) | Specialized / Rogers | $85.00 – $250.00+ | Very High |

| Flexible PCB | Polyimide | $45.00 – $120.00 | Specialized |

5. Regional Cost Comparison: China vs. North America vs. Europe

Geographic location continues to be a massive lever in the cost to manufacture a PCB board. While 2026 has seen a surge in "nearshoring" for critical defense and medical components, China remains the global leader in cost-to-performance ratios for consumer and industrial electronics.

- China: The undisputed leader for mass production. Large-scale automation has kept labor costs relatively flat despite rising energy prices. Shipping logistics in 2026 are highly optimized, though import duties must be factored into the final landed cost.

- North America: Primarily focused on R&D, prototyping, and high-reliability aerospace boards. The cost to manufacture a PCB board in the US or Canada can be 3 to 5 times higher than in Asia, but it offers better IP protection and zero-day communication benefits.

- Eastern Europe: A growing middle ground. Countries like Poland and Romania offer a 30% discount over Western European prices while providing proximity to major EU automotive markets.

6. Prototyping vs. Mass Production Financials

The cost to manufacture a PCB board scales non-linearly. For a prototype run of 5–10 boards, you are essentially paying for "Setup and Engineering" rather than material. A single prototype might cost $200, whereas the same board in a run of 10,000 units might drop to $2.50.

Professional Tip: In 2026, many manufacturers offer "Quick Turn" prototypes. Be aware that reducing lead time from 10 days to 48 hours can increase the cost to manufacture a PCB board by as much as 300%. If your project timeline allows, always opt for standard lead times to preserve your budget.

7. Don't Ignore the Hidden Costs: Testing and NRE

When a manufacturer quotes a price, they often omit "Non-Recurring Engineering" (NRE) charges. These are one-time fees for stencil creation, pick-and-place programming, and electrical test fixture setup. For a medium-complexity board, NRE can range from $300 to $1,500.

Furthermore, testing is a critical component of the cost to manufacture a PCB board. Basic Flying Probe testing is often included, but advanced Bed-of-Nails testing, X-Ray inspection for BGA (Ball Grid Array) components, and functional testing can add $5 to $50 per unit. In 2026, skipping these tests is considered high-risk due to the extreme density of modern circuits.

8. 5 Strategies to Lower Your PCB Manufacturing Costs

- Optimize Trace Width/Spacing: Avoid pushing the manufacturer’s limits. If a factory can produce 3/3 mil traces but your design works at 6/6 mil, you will save significantly by reducing the precision requirement.

- Standardize Via Sizes: Every time you change drill bit sizes, the machine must stop. Reducing the variety of drill sizes on your board can shave time—and cost—off the production run.

- Choose HASL over ENIG: Unless you are working with fine-pitch BGA components or require extreme shelf-life, Hot Air Solder Leveling (HASL) is much cheaper than Electroless Nickel Immersion Gold (ENIG).

- Consolidated Panelization: If you are manufacturing several small boards, combine them into one larger panel yourself. This reduces the number of NRE setup fees.

- Engage DFM Early: Work with partners like Wintech during the design phase. Design for Manufacturing (DFM) reviews can identify costly "impossible" geometries before you commit to a production run.

9. Executive Summary Table

| Cost Factor | Impact Intensity | 2026 Trend |

|---|---|---|

| Base Material (FR4 vs Specialized) | High | 35% increase in copper/resin inputs |

| Layer Count (4 vs 8 vs 12) | Extreme | Exponential increase due to HDI requirements |

| Surface Finish (HASL vs ENIG) | Moderate | ENIG becoming more common for AI tech |

| Production Region | Extreme | China remains 70% cheaper for mass runs |

| Testing & QA | High | AI-automated AOI reducing human error costs |

10. Frequently Asked Questions

For a standard 10x10cm board in quantities of 100+, you can expect to pay between $1.00 and $5.00 per unit for fabrication, excluding components and assembly.

Small runs cannot distribute the fixed "setup costs" (NRE) over a large number of units. The machine programming and stencil creation costs remain the same whether you make 5 boards or 5,000.

Generally, green is the standard and cheapest. Colors like white, black, or blue may add a 10-15% premium and increase lead times because the manufacturer must perform a "wash-out" of the machines between colors.

The total cost is the sum of: Bare Board Fabrication + Component Sourcing + Assembly Labor ($0.02 - $0.05 per solder joint) + Testing + Shipping.

11. References

1. St. Louis Fed. "Producer Price Index: Bare Printed Circuit Board Manufacturing (2026 Forecast)."

2. Mordor Intelligence. "Printed Circuit Board Industry Size & Trends Report 2030."

4. IEEE Spectrum. "The Impact of Copper Foil Volatility on Electronics Manufacturing Costs." (2026).