PCB Circuit Board Price 2026: Trends, Cost Drivers, and Industrial Forecast

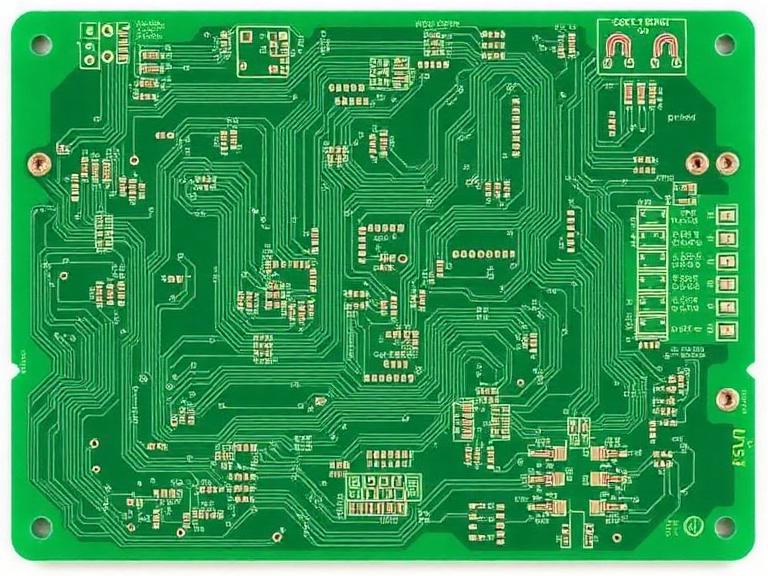

The global electronics landscape has entered a transformative phase in 2026. As the demand for AI servers, electric vehicles (EVs), and high-frequency 5G/6G communication peaks, the pcb circuit board price has become a central concern for hardware engineers and procurement leaders. After several years of supply chain recalibration, 2026 presents a unique pricing structure influenced by rising copper foil premiums, green manufacturing mandates, and advanced miniaturization technologies. Understanding the nuances of the pcb circuit board price is no longer just about volume—it is about the strategic integration of materials and manufacturing efficiency.

2026 Global PCB Market Dynamics

The pcb circuit board price in 2026 is projected to stabilize following the "Material Shortage Year" of late 2025. According to recent market reports, the global PCB market size is expected to reach 81.91 billion USD this year, growing at a CAGR of 5.3%. This growth is heavily skewed toward high-density interconnect (HDI) boards and flexible PCBs, which command higher premiums due to the specialized equipment required for their production. While standard FR-4 laminates remain the volume leader, the price of high-TG and heavy-copper boards used in the automotive sector has seen a 15% increase due to specialized resin requirements and copper foil processing fees.

Industrial Partner: Wintech Electronics

Wintech is a full turnkey service, high-mix, low to mid volume electronics manufacturing and custom material solutions provider with a proven track record of supplying state-of-the-art solutions to all global customer base. We offer tailor made solutions for our customers: high level, high difficult, large size, complex structure, high precision PCB Layout, PCBAs and turnkey complete products full systems electronic contract manufacturing solutions, prototyping, low to mid volume, mass production. Many of world's top 500 enterprises have cooperated with us for many years, Wintech is worth relying on.

Our comprehensive services include:

Primary Drivers of Pcb Circuit Board Price

Calculating the pcb circuit board price involves a multi-variable equation. In 2026, the three most significant factors are raw material volatility, labor/utility overhead, and design complexity.

Raw Material Volatility

Materials typically account for 55% to 65% of the total manufacturing cost. In 2026, high-end copper foil (HVLP4) has faced a supply gap of nearly 25%, leading to price hikes of approximately 2 USD per kg. Additionally, the transition to 1.6T switch architectures and 800G networking has pushed demand for M9-grade CCL (Copper Clad Laminates), which use quartz fabric that costs significantly more than standard E-glass. This material shift has a direct, non-linear impact on the pcb circuit board price for high-computing applications.

Labor and ESG Compliance

Labor and utility costs now account for 65% to 80% of production costs in high-automation regions. 2026 has seen the implementation of "Green Fab" standards, where Environmental, Social, and Governance (ESG) compliance is no longer optional. Manufacturers are investing in closed-loop water systems and additive manufacturing to reduce waste, which carries a short-term capital expenditure premium that is reflected in the unit pcb circuit board price.

Layer Count and Material Impact on Costs

The relationship between layer count and the pcb circuit board price remains exponential rather than linear. Each additional layer requires more lamination cycles, etching steps, and complex drilling (such as blind and buried vias).

- 1-2 Layers: The baseline for cost-effectiveness, suitable for simple IoT sensors and LED drivers.

- 4-6 Layers: The standard for most modern consumer electronics. In 2026, 4-layer boards typically cost 2x to 2.5x the price of 2-layer boards.

- 8-12+ Layers: Necessary for impedance-matched high-speed signals. The pricing for these boards often includes a "complexity premium" for signal integrity testing and X-ray inspection.

Prototype vs. Mass Production Pricing

Economy of scale remains the most powerful tool to reduce the pcb circuit board price. For 2026, prototype runs (1-10 pieces) often range from 50 USD to 200 USD per board due to setup and engineering (NRE) charges. In contrast, mass production (10,000+ units) can drop the per-unit cost to between 2 USD and 15 USD for similar specifications. Leveraging a provider like Wintech, which offers both Quick Turn Fast PCB Prototype Assembly and seamless transition to mass production, can significantly reduce the "hidden costs" of design revisions.

2026 Cost Comparison Table

| PCB Type / Complexity | Standard Price Range (USD/sq in) | Key Application (2026) | Price Trend |

|---|---|---|---|

| Single/Double Sided | 0.08 - 0.15 | IoT Sensors / Power Supplies | Stable |

| 4-6 Layers (FR-4) | 0.25 - 0.40 | Consumer Electronics / Tablets | Moderate Increase |

| HDI / High-Speed | 0.55 - 0.95 | AI Servers / 5G Infrastructure | Rising (Material Gap) |

| Flexible / Rigid-Flex | 0.45 - 0.80 | Wearables / Medical Devices | Stable (Tech Maturity) |

| Heavy Copper / High-TG | 0.60 - 1.20 | EV Battery Systems / ADAS | Significant Increase |

Frequently Asked Questions

Why has the pcb circuit board price increased for high-end servers in 2026?

The rise is primarily due to the "computing power premium." High-end servers now require M9 laminates and HVLP4 copper foil to manage 224Gbps transmission speeds. These materials are in short supply, and their processing costs have risen by 10% to 20% compared to last year.

How can I reduce the pcb circuit board price during the design phase?

Optimizing board dimensions to fit standard panels, reducing layer counts through smart routing, and standardizing on common FR-4 materials are the most effective ways. Additionally, choosing a turnkey provider like Wintech can help eliminate extra logistics and sourcing markups.

Is the price of gold affecting PCB costs in 2026?

Yes. The price of gold has driven manufacturing costs for ENIG (Electroless Nickel Immersion Gold) surface finishes up by as much as 37%. For cost-sensitive projects, manufacturers are increasingly recommending OSP (Organic Solderability Preservatives) as a budget-friendly alternative.

Technical References

- Research Nester (2025). "Global Printed Circuit Board Market Size & Trends Forecast 2035."

- Fubon Securities (Oct 2025). "2026 PCB Industry Outlook: Materials Enable Computing Power."