7 steps to Assemble Electronics: A Complete Guide for 2025

Table of Contents

- Introduction

- About Wintech: Turnkey Electronics Manufacturing

- Electronic Assembly Process Overview

- Step-by-Step Guide to Assembling Electronics

- Tools and Equipment Required

- Tips for Successful Assembly

- Common Mistakes to Avoid

- Why Choose Wintech for Electronic Assembly?

- Summary Table

Introduction

Assembling electronics is a complex but rewarding process that combines precision, knowledge, and technology. Whether you're developing a prototype or working on a full production run, understanding how electronic assembly works is essential in 2025. From PCBs to complete systems, accuracy and quality are key.

About Wintech: Turnkey Electronics Manufacturing

Wintech is a global leader in high-mix, low to mid-volume electronics manufacturing. Offering full turnkey services, Wintech provides customized solutions for highly complex, large, and high-precision electronic assemblies. Trusted by Fortune 500 companies worldwide, Wintech's services include:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction (NPI)

- Plastic Molding

- Metal Precision Machining

Electronic Assembly Process Overview

Electronic assembly involves integrating various electronic components into a printed circuit board (PCB) to form a fully functional system. The process typically includes:

- PCB design and manufacturing

- Component sourcing

- Surface Mount Technology (SMT) and Through-Hole Assembly

- Inspection and testing

- Final assembly and packaging

Step-by-Step Guide to Assembling Electronics

Step 1: Schematic Design and BOM Creation

- Use design software (e.g., Altium Designer or Eagle) to create the circuit.

- Generate a Bill of Materials (BOM) with component part numbers and specifications.

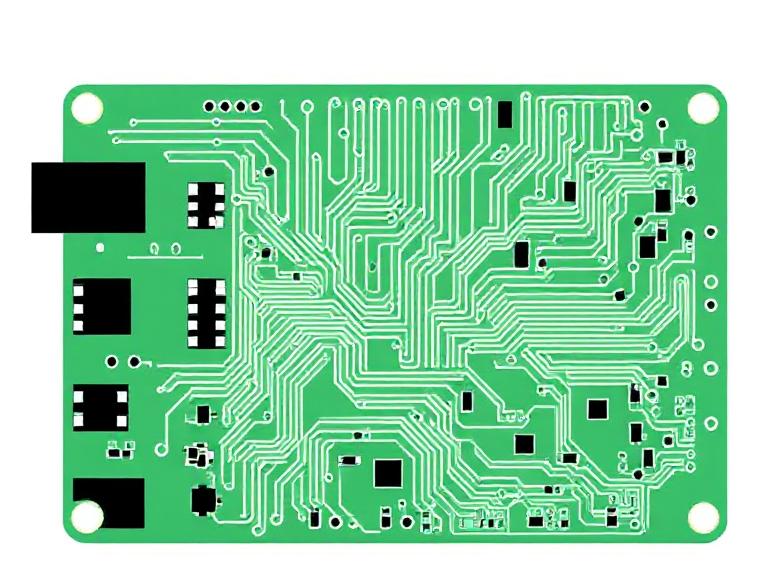

Step 2: PCB Layout Design

- Design the PCB layout, ensuring proper trace routing and component placement.

- Wintech offers high-precision PCB layout services for complex structures.

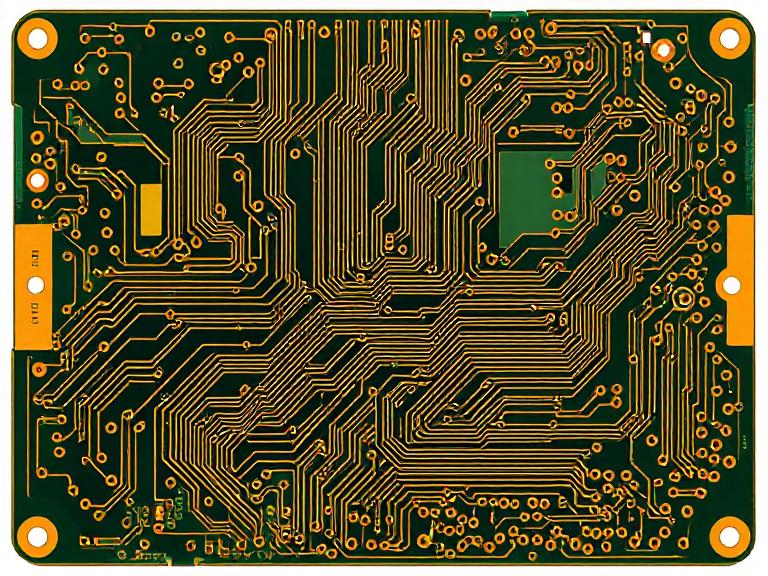

Step 3: PCB Fabrication

- Submit Gerber files to a reliable manufacturer like Wintech.

- Choose board material, layer count, finish, and thickness.

Step 4: Component Procurement

- Source components according to the BOM.

- Ensure all parts are RoHS-compliant and quality verified.

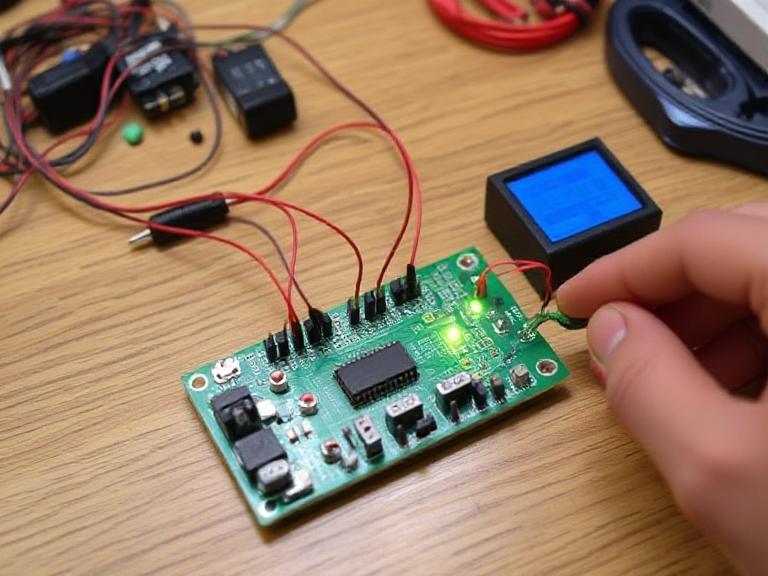

Step 5: PCB Assembly (SMT and THT)

- SMT: Components are placed on the PCB using pick-and-place machines, followed by reflow soldering.

- THT: Through-hole components are manually or automatically inserted and soldered using wave soldering.

Step 6: Inspection and Testing

- Use Automated Optical Inspection (AOI), X-ray, and Functional Testing to ensure board quality.

- Correct any identified issues through rework stations.

Step 7: Final Assembly

- Assemble the full product including housing, connectors, and cables.

- Perform final functionality tests before packaging.

Tools and Equipment Required

Depending on the scale and complexity, assembling electronics can require:

- Soldering station or reflow oven

- Multimeter and oscilloscope

- Pick-and-place machine (for high volume)

- Microscope or magnifier

- Component tweezers and cutters

- ESD protection gear

Tips for Successful Assembly

- Always work in an ESD-safe environment.

- Double-check component orientation before soldering.

- Keep a clean and organized workspace.

- Use high-quality solder paste and flux.

- Test frequently during the assembly process.

Common Mistakes to Avoid

- Incorrect placement of polarized components (e.g., diodes, electrolytic capacitors)

- Cold solder joints or excessive solder

- Insufficient testing before power-up

- Neglecting thermal management in the design stage

Why Choose Wintech for Electronic Assembly?

Wintech combines engineering excellence, global supply chain access, and world-class manufacturing capabilities to deliver reliable, efficient, and cost-effective electronic assembly solutions:

- High-level and high-difficulty assemblies

- Large-size and complex structures

- Prototyping to mass production support

- Dedicated engineering support for new product introductions

Summary Table

| Assembly Stage | Description | Wintech Advantage |

|---|---|---|

| Schematic & BOM | Design circuit and list components | Professional layout and BOM validation |

| PCB Layout & Fabrication | Design and produce circuit boards | High precision & complex structure handling |

| Component Sourcing | Procure quality parts | Global supply chain access |

| Assembly (SMT & THT) | Mount components on the board | Full SMT/THT capability with quick-turn |

| Testing | Ensure functionality and quality | Advanced AOI, X-ray, and FCT testing |

| Final Product Build | Enclosure, wiring, and packaging | Turnkey box build solutions |

Conclusion: Assembling electronics in 2025 requires not just tools and components, but also precision, expertise, and quality assurance. With Wintech’s end-to-end services, from PCB design to full system integration, you can ensure that every electronic product meets the highest standards of performance and reliability.