Can a PCB Board Be Repaired

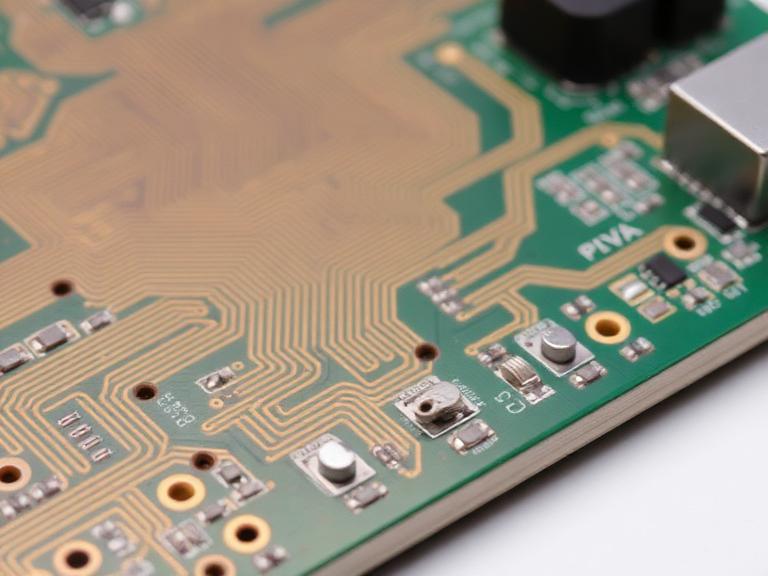

In the fast-paced world of electronics, Printed Circuit Boards (PCBs) act as the central nervous system for virtually every device we use, from simple household appliances to complex industrial machinery. However, electronic failures are inevitable. Whether due to manufacturing defects, environmental stress, or component burnout, a damaged board can bring operations to a halt. This leads to a critical question for manufacturers and consumers alike: can a PCB board be repaired effectively, or is replacement the only option?

The short answer is yes. In the vast majority of cases, a PCB board can be repaired. However, the feasibility, cost-effectiveness, and reliability of that repair depend on the extent of the damage and the skill of the technician. This comprehensive guide will explore the intricacies of PCB repair, the methods used to salvage damaged boards, and how industry leaders like Wintech are setting the standard for electronic rework and manufacturing.

Table of Contents

- 1. Understanding PCB Damage: Why Do Boards Fail?

- 2. Can a PCB Board Be Repaired? Assessing Feasibility

- 3. Common Types of Repairable PCB Issues

- 4. The PCB Repair Process: Techniques and Tools

- 5. Wintech: Your Partner in Electronics Manufacturing and Repair

- 6. Repair vs. Replace: The Economic Decision

- 7. Prevention: Extending the Life of Your PCB

- 8. Summary Comparison Table

- 9. Frequently Asked Questions (FAQs)

1. Understanding PCB Damage: Why Do Boards Fail?

Before we can fully answer "can a PCB board be repaired," we must understand what causes them to fail. PCBs are rugged, but they are not indestructible. They operate in environments that subject them to heat, vibration, and electrical stress.

Physical Damage

Physical damage is often the most visible form of failure. This can occur during the manufacturing process, shipping, or the device's operational life. Dropping a device can crack the PCB substrate, severing internal connections. Additionally, improper handling can lead to scratches that cut through copper traces.

Thermal Stress

Electronics generate heat. If a PCB is not designed with adequate thermal management, or if it operates in an environment exceeding its temperature rating, the board can suffer. Excessive heat can cause delamination (where the layers of the board separate), lift copper pads, or burn out sensitive components.

Environmental Factors

Moisture, dust, and chemical contaminants are enemies of the circuit board. Corrosion is a leading cause of failure, particularly in industrial or outdoor settings. When moisture meets electricity, electrochemical migration can occur, creating shorts that destroy the board's functionality.

2. Can a PCB Board Be Repaired? Assessing Feasibility

When a board fails, the immediate reaction is often to discard it. However, asking can a PCB board be repaired is a smart financial move. Professional rework can save up to 70% of the cost of a new board. The feasibility of repair depends on three main factors:

- Complexity of Damage: A simple blown capacitor is easily fixed. A cracked multi-layer board with severed internal traces is much harder and may be economically unviable.

- Availability of Parts: For legacy equipment, finding replacement components can be difficult. However, a skilled rework center can often source alternatives.

- Board Value: For a cheap, mass-produced consumer toy, replacement is better. For a high-value industrial controller or a custom aerospace board, repair is almost always the preferred path.

3. Common Types of Repairable PCB Issues

To understand the scope of can a PCB board be repaired, we should look at the specific issues that technicians resolve daily.

Broken Traces

Traces are the copper highways that carry electricity across the board. If a trace is cut (due to a scratch or crack), the circuit opens, and the device fails. Technicians can repair this by bridging the gap with a jumper wire or carefully soldering a new piece of copper over the break.

Damaged Pads

Pads are the metal surfaces where components are soldered. Excessive heat during desoldering or physical force can rip these pads off the substrate. Repair involves using specialized epoxy to bond a new copper pad to the board and reconnecting it to the trace.

Component Failure

This is the most common repair scenario. Capacitors leak, resistors burn out, and integrated circuits (ICs) fail. Repairing this involves desoldering the defective component and soldering a new one in its place. This requires precision, especially for Surface Mount Technology (SMT) components.

4. The PCB Repair Process: Techniques and Tools

Professional repair is vastly different from DIY soldering. It requires a controlled environment and specialized tools to ensure the repair is reliable.

Diagnostics and Inspection

The first step is identifying the fault. Technicians use multimeters, oscilloscopes, and automated optical inspection (AOI) systems to pinpoint the issue. Thermal imaging cameras are also used to spot overheating components.

Soldering and Desoldering

Removing a damaged component without harming the board is an art. Technicians use hot air rework stations that melt solder on all pads simultaneously, allowing the component to be lifted gently. For through-hole components, vacuum desoldering pumps suck away the molten solder.

Conformal Coating Removal and Reapplication

Many boards are protected by a conformal coating. To fix the board, this coating must be chemically or mechanically removed. Once the repair is complete, the coating is reapplied to ensure future protection against moisture and dust.

5. Wintech: Your Partner in Electronics Manufacturing and Repair

About Wintech

When asking can a PCB board be repaired, the answer often relies on the capability of your service provider. Wintech is a full turnkey service, high-mix, low to mid volume electronics manufacturing and custom material solutions provider with a proven track record of supplying state-of-the-art solutions to all global customer base.

We provide tailor-made solutions for our customers: high level, high difficult, large size, complex structure, high precision PCB Layout, PCBAs and turnkey complete products full systems electronic contract manufacturing solutions. From prototyping to low to mid-volume and mass production, many of the world's top 500 enterprises have cooperated with us for many years. Wintech is worth relying on.

Our Comprehensive Services Include:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

- Backplanes & Sever Chasis

- Cable Harness & Assembly

- Cabinet & Panel PLC Wiring

- Electro-Mechanical Assembly

- Turnkey Box Build

- Repair And Rework

Whether you need a new build or specialized Repair And Rework services for complex assemblies, Wintech has the expertise to deliver.

6. Repair vs. Replace: The Economic Decision

Businesses constantly weigh the options of repair versus replacement. Understanding the economics helps clarify can a PCB board be repaired profitably.

The Cost Factor

Generally, if the repair cost is less than 50-60% of the replacement cost, repair is the logical choice. However, for legacy systems where the board is no longer manufactured (Obsolescence), the replacement cost might be infinite (requiring a full system upgrade). In these cases, repair is the only option.

Lead Time

Ordering a new custom PCB can take weeks or months depending on the supply chain. A professional repair can often be completed in days. For production lines where downtime costs thousands of dollars per hour, speed is the primary driver for repair.

Environmental Impact

E-waste is a massive global issue. Repairing boards keeps heavy metals and plastics out of landfills. Companies with green initiatives prioritize repair to reduce their carbon footprint.

7. Prevention: Extending the Life of Your PCB

While asking can a PCB board be repaired is necessary when failure occurs, prevention is better. There are steps you can take to minimize the need for repairs.

- Regular Maintenance: Clean dust from fans and vents to prevent overheating.

- Environmental Control: Keep electronics in temperature-controlled environments with low humidity.

- Power Conditioning: Use surge protectors and uninterruptible power supplies (UPS) to prevent voltage spikes from damaging components.

- Proper Design: Working with a top-tier manufacturer like Wintech ensures your boards are designed with proper thermal management and robust materials from the start.

8. Summary Comparison Table

The table below summarizes common PCB faults and their repairability status.

| Fault Type | Repairable? | Complexity | Typical Repair Method |

|---|---|---|---|

| Blown Fuse/Capacitor | Yes | Low | Desolder old, solder new component. |

| Broken Trace | Yes | Medium | Jumper wire or trace reconstruction. |

| Lifted Pad | Yes | High | Epoxy bonding and plating. |

| Corrosion | Yes (Surface) | Medium | Chemical cleaning and trace repair. |

| Burnt Substrate | Depends | Very High | Excavation and epoxy fill (often risky). |

| Delamination | No | N/A | Board replacement usually required. |

9. Frequently Asked Questions (FAQs)

Yes, but time is of the essence. Water damage causes corrosion and shorts. If the board is cleaned immediately with ultrasonic cleaners and isopropyl alcohol, it can often be saved. However, if the water caused a major short circuit that burned internal layers, it might be unrecoverable.

The cost varies significantly. A simple component swap might cost $50-$100, while complex industrial board rework could cost $500+. However, compared to replacing a $5,000 control board, the repair is highly economical.

Yes, but it is challenging. Surface damage on a multi-layer board is repairable. If the damage penetrates the inner layers (power planes or signal layers), repair is extremely difficult and requires advanced excavation techniques that not all repair shops can perform.

Yes, Wintech offers comprehensive repair and rework services. Our expertise in complex structures and high-precision layouts allows us to analyze and repair boards from various origins.

Yes. This is a common repair. Technicians use adhesive copper tape or jumper wires to recreate the electrical path. It may not look as pretty as the original manufacturing, but it is functionally identical.

Conclusion

So, can a PCB board be repaired? Absolutely. With the right expertise, tools, and partners, extending the life of your electronic assets is not only possible but also smart business. Whether you are dealing with a minor component failure or complex trace damage, professional rework can restore functionality and save significant capital.

For those looking for high-quality manufacturing to prevent these issues, or expert rework services to fix them, Wintech stands ready to assist with a proven track record of excellence in the global electronics industry.