6 Best LED Light PCB Boards in 2025

Table of Contents

- Introduction

- Essential Qualities of Top LED PCB Boards

- 1. High-Heat Alu-Core PCB

- 2. Rigid-Flex LED PCB

- 3. High-Density FR-4 LED PCB

- 4. Flexible LED Strip PCB

- 5. MCPCB with Thermal Via Matrix

- 6. Custom Turnkey LED PCBA from Wintech

- About Wintech’s Turnkey Services

- How to Select the Right LED PCB

- Summary Table

Introduction

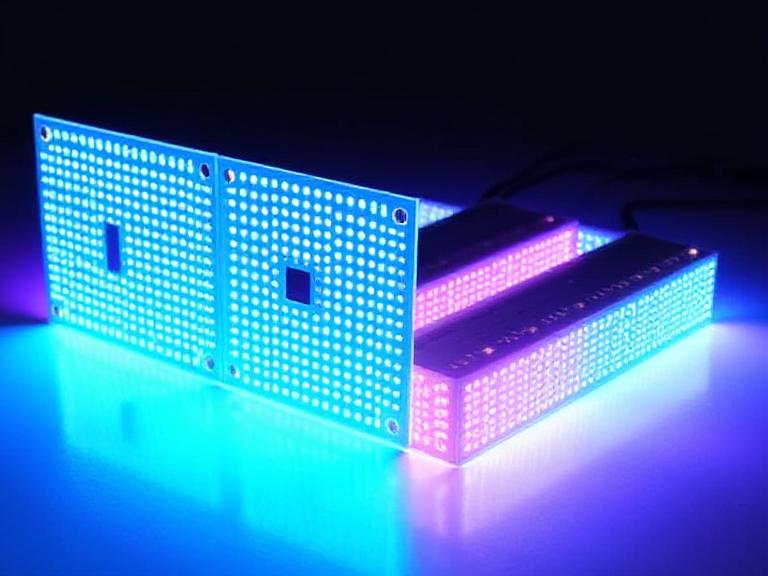

LED lighting continues to dominate the industry, thanks to efficiency, longevity, and design flexibility. At the heart of every LED lamp or fixture lies its PCB—the core foundation that influences performance, heat management, and durability. In this guide, we explore the 6 best LED light PCB boards of 2025: materials, features, and manufacturers, including insights from precision provider Wintech.

Essential Qualities of Top LED PCB Boards

- Thermal Performance: Effective heat dissipation to maintain brightness and lifespan .

- Mechanical Stability: Dimensional stability across temperature ranges .

- Material Compatibility: Matching board type to application—flexible, rigid, metal-core.

- Manufacturing Quality: Precision layout, trace reliability, low CTE boards from leading producers .

- Turn-Key Capability: Full-service solutions from prototyping to mass production.

1. High-Heat Aluminum-Core PCB

Ideal for high-power applications such as outdoor floodlights and industrial luminaires. Featuring an aluminum core with thermal vias and a dielectric layer, these boards offer excellent heat transfer from LEDs to the housing .

- Aluminum core enables better thermal management than traditional FR-4

- Resists warping and thermal cycling—suitable for harsh settings

- Common in automotive, street lighting, and signage

2. Rigid-Flex LED PCB

Perfect for compact fixtures, strip lights, and foldable designs. Combines rigid sections for high-density components with flexible connectors for creative form factors.

- Allows 3D form designs without wiring harnesses

- Reduces assembly errors by integrating rigid and flex in one board .

- Used in wearable illuminators, architectural LEDs, and tight-space installations

3. High-Density FR-4 LED PCB

Standard FR-4 boards remain popular due to low cost and ease of fabrication. Best suited for lower-power indoor lighting where heat is manageable.

- Ideal for decorative and indoor panel lighting

- Enables dense component placement and fine trace routing.

- Suitable where thermal demands are moderate

4. Flexible LED Strip PCB

Widely used in accent lighting, signage, and backlighting. FPCBs are crafted on polyimide or PET, featuring solder pads and thin copper traces for flexibility.

- Flexible boards bend and fold—ideal for curved fixtures

- SMD LEDs directly mounted—simpler assembly

- Common in retail, hospitality, and decorative lighting

5. MCPCB with Thermal Via Matrix

Metal Core PCBs (MCPCB) reinforced with thermal via matrices enable vertical heat transfer from the LED pad to the base layer.

- Optimizes thermal conduction for high-wattage LEDs

- Resists expansion while supporting large LED arrays

- Used in high-output grow lights, industrial fixtures

6. Custom Turnkey LED PCBA from Wintech

Wintech offers tailored, one-stop LED PCB assembly solutions—from layout to full-system turnkey PCBA—perfect for mid-volume production.

- High-precision PCB Layout & Assembly for LED modules

- Low-to-mid volume flexibility with mass-production readiness

- Used by top global brands, accredited by Fortune 500 collaborations

About Wintech’s Turnkey Services

Wintech offers comprehensive services including PCB design, manufacturing, SMT assembly, prototyping, plastic molding, and metal machining. With a reputation for handling high-mix, medium-volume orders for global clients, including top 500 enterprises, Wintech excels in technical complexity and quality reliability.

Services Highlights

- Precision PCB design/layout & advanced assembly processes

- Prototype to full-turnkey manufacturing in controlled volumes

- Added value via plastic molding and metal machining

- Commitment to quality and timeliness—ideal for lighting innovators

How to Select the Right LED PCB

- Assess thermal budget: Match board type to LED wattage and heat dissipation needs.

- Consider shape/size: Use flex or rigid-flex for curvy or compact fixtures.

- Production volume: Turnkey preferred for batch consistency; rigid FR-4 for high volume.

- Environmental requirements: Choose aluminum or MCPCB for rugged conditions.

- Manufacturer capabilities: Select one-stop providers like Wintech for streamlined production.

Summary Table

| # | PCB Type | Key Feature | Ideal Application |

|---|---|---|---|

| 1 | Alu-Core PCB | Excellent heat dissipation | High-power street/flood lights |

| 2 | Rigid-Flex PCB | Formable, space-saving | Wearables, curved fixtures |

| 3 | High-Density FR-4 | Low cost, dense layout | Indoor panels, signs |

| 4 | Flexible Strip PCB | Bendable, continuous strips | Backlighting, decorative strips |

| 5 | MCPCB with Vias | Thermal via heat transfer | Industrial/high-output lighting |

| 6 | Wintech Turnkey PCBA | Full-service LED module | Custom mid-volume production |