Cheap Printed Circuit Board Assembly Services 2025

Table of Contents

- Introduction

- Why PCB Assembly Matters in 2025

- China PCB Assembly Overview

- Advantages of China Printed Circuit Board Assembly

- Wintech Technology – Company Profile

- Step-by-Step PCB Assembly Process

- Applications and Industries Served

- Cost-Saving Strategies for PCB Assembly

- How to Choose the Right PCB Assembly Provider

- Key Takeaways

- References

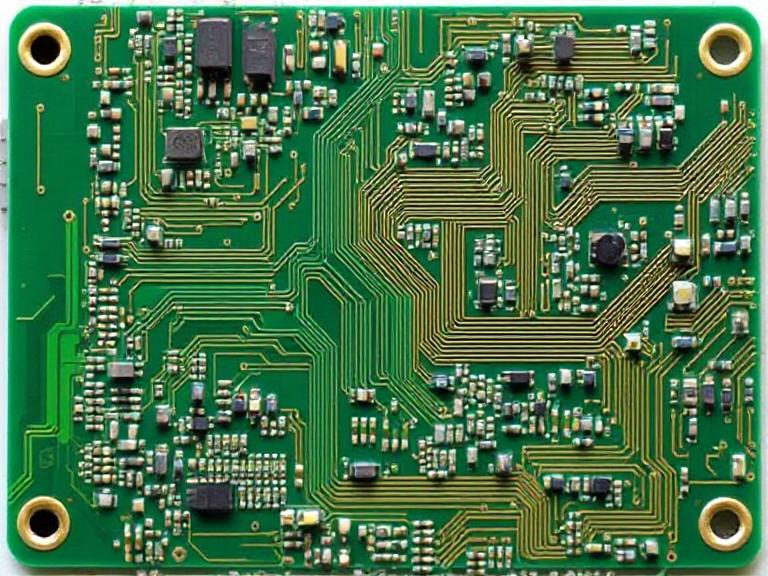

Introduction Printed Circuit Board Assembly Services

Why PCB Assembly Matters in 2025

The Growing Electronics Industry

The global electronics industry continues to expand rapidly in 2025, driven by IoT devices, AI systems, and electric vehicles. PCBs are the backbone of these devices, serving as the foundation for electrical connectivity and functionality.Importance of High-Quality Assembly

A well-assembled PCB ensures:- Reliability: Minimizes device failure rates.

- Performance: Maintains signal integrity and power distribution.

- Scalability: Allows for efficient mass production.

- Compliance: Meets international quality standards.

China PCB Assembly Overview

China remains the largest global hub for PCB manufacturing and assembly due to its:- Low production costs compared to Western countries.

- Skilled labor force trained in advanced assembly techniques.

- Robust supply chain for components and raw materials.

- State-of-the-art facilities capable of producing high-volume and prototype batches.

Advantages of China Printed Circuit Board Assembly

1. Cost Efficiency

Manufacturing in China offers **significant cost savings** due to lower labor costs, bulk purchasing, and streamlined logistics.2. Rapid Prototyping

China PCB providers specialize in **quick-turn prototyping**, allowing start-ups and R&D teams to test their designs faster.3. High-Volume Production

Whether you need **low-volume prototypes** or **large-scale production runs**, China facilities can handle diverse volume requirements.4. Advanced Technology

Providers like Wintech utilize:- Automatic SMT (Surface Mount Technology) lines

- Wave soldering and selective soldering equipment

- Automated Optical Inspection (AOI)

- ICT (In-Circuit Testing) and Functional Testing

Wintech Technology – Company Profile

Key Highlights:

- Military Quality Standards: Trusted by clients with mission-critical requirements.

- Versatile Production Lines: Support for FR4, Rogers, metal core aluminum, copper, duroid, ceramic, CEM 1, and CEM 3 substrates.

- Flexible Manufacturing: Continuous, automatic, and cellular line configurations for various product mixes.

- Leaded & RoHS Options: Segregated inventory and production areas for compliance.

- Over 20 Years Experience: Serving start-ups and global enterprises alike.

Step-by-Step PCB Assembly Process

1. PCB Fabrication

Boards are fabricated to meet customer specifications, including **layer count, thickness, and copper weight**.2. Component Sourcing

Wintech offers **turnkey services**, sourcing all necessary components from trusted suppliers.3. SMT Assembly

Surface-mount devices are placed and soldered using **high-speed pick-and-place machines**.4. Through-Hole Assembly

For components requiring through-hole mounting, **wave soldering** or **manual soldering** is performed.5. Inspection & Testing

Rigorous quality checks include:- AOI (Automated Optical Inspection)

- X-ray inspection (for BGA packages)

- Functional Testing

- In-Circuit Testing

6. Packaging & Delivery

Finished assemblies are **anti-static packaged** and shipped to customers worldwide.Applications and Industries Served

Wintech provides PCBA services for:- Consumer Electronics

- Telecommunications Equipment

- Automotive Electronics

- Medical Devices

- Industrial Controls

- Military & Aerospace Applications

- IoT Devices & Smart Home Solutions

Cost-Saving Strategies for PCB Assembly

Design for Manufacturability (DFM)

Optimize PCB layout to reduce manufacturing complexity and minimize production costs.Bulk Ordering

Larger order quantities help achieve **economies of scale**.Choosing Local Suppliers

Component sourcing within China lowers logistics costs and lead times.Lean Manufacturing

Wintech follows **lean principles** to minimize waste and enhance schedule flexibility.How to Choose the Right PCB Assembly Provider

When selecting a PCB assembly provider, consider:- Experience: Look for a company with a proven track record (like Wintech).

- Quality Standards: ISO certifications, RoHS compliance, IPC-A-610 standards.

- Turnaround Time: Ability to meet your deadlines.

- Technical Support: Engineering support for prototyping and DFM feedback.

- Cost Transparency: Clear pricing with no hidden charges.

Key Takeaways

| Key Aspect | Summary |

|---|---|

| Provider | China Wintech Technology Co., Ltd. |

| Strengths | Military-quality standards, flexible production lines, cost-effective solutions |

| Industries Served | Consumer, Automotive, Telecom, Medical, Military, IoT |

| Cost Savings | Lean manufacturing, bulk orders, local sourcing |

| Location Advantage | Shenzhen, China – low cost and skilled workforce |

| Ideal Clients | Start-ups, R&D teams, large electronics manufacturers |

References

- China Wintech Technology Official Website

- IPC PCB Assembly Standards

- Electronics Weekly – PCB Industry Updates

Recent Posts

Top 8 Custom Printed Circuit Assembly Suppliers 2026: The...

As we navigate through 2026, the electronics...

8 Best Printed Circuit Assembly Suppliers 2026

As we navigate 2026, the electronics manufacturing...

7 Functions of Electronics Manufacturing Services: A...

1. Introduction to the EMS Landscape

As we navigate...

How Much Does It Cost to Manufacture a PCB Board 2026?

Navigating the electronics landscape in 2026...

PCB Circuit Board Price 2026: Trends, Cost Drivers, and...

The global electronics landscape has entered a...

Are PCBs Safe to Touch? A Deep Dive into Electronic Handling...

Printed Circuit Boards (PCBs) are the nervous systems of...

What is Substrate-Like PCB (SLP)? The Next Frontier in...

As we navigate through 2026, the electronics industry is...

10 Top PCB Board Manufacturers 2026: Who Leads the Industry?

The electronics industry is undergoing a seismic shift as...

What is Pcb on pcb design?

In the rapidly evolving landscape of electronics in 2026,...

9 Best PC Board Makers 2026: The Ultimate Guide to PCB...

The electronics industry in 2026 is moving at a...