10 Basic Rules of PCB Circuit Board Design You Need to Know

Table of Contents

- Introduction to PCB Design

- 1. Understand Your Circuit Requirements

- 2. Select the Right PCB Material

- 3. Choose an Appropriate Layer Stackup

- 4. Component Placement Is Crucial

- 5. Follow Proper Trace Routing Practices

- 6. Use Effective Grounding Strategies

- 7. Ensure Signal Integrity

- 8. Design for Manufacturability (DFM)

- 9. Run DRC, DFM, and ERC Checks

- 10. Collaborate with an Experienced PCB Partner

- Summary Table: Top 10 PCB Design Rules

Introduction to PCB Design

Printed Circuit Boards (PCBs) are at the heart of every electronic product, from smartphones to industrial machinery. Designing a PCB correctly is critical for the product's performance, manufacturability, and reliability. Whether you’re a beginner or a seasoned engineer, understanding the fundamental PCB design principles is vital.

Wintech is a trusted leader in high-mix, low-to-mid volume electronics manufacturing. With services ranging from PCB design and layout to complete turnkey electronic manufacturing solutions, Wintech supports global customers—including many of the world’s top 500 companies—with precision, reliability, and speed.

1. Understand Your Circuit Requirements

Start with a complete schematic and electrical understanding

Every good PCB design begins with a complete understanding of the circuit it supports.

Steps to follow:- Define power requirements and signal types

- Classify analog vs. digital areas

- Estimate current flow and voltage levels

- Outline functional blocks and interconnections

Tip: Use professional EDA tools like Altium Designer or Eagle to create your schematic.

2. Select the Right PCB Material

Material choice affects performance, cost, and durability

Your choice of substrate (FR4, polyimide, ceramic, etc.) can impact signal integrity, thermal management, and manufacturing cost.

Common material considerations:- FR4: Standard for most applications

- Rogers: Ideal for high-frequency circuits

- Polyimide: Best for flexible PCBs

- Ceramic: High power and heat dissipation needs

Wintech offers tailor-made solutions with high precision material engineering suited for all levels of complexity.

3. Choose an Appropriate Layer Stackup

Proper stackup ensures electrical and mechanical integrity

Designers must balance performance and manufacturability when deciding on the number of layers and their arrangement.

Layering tips:- Use at least 4 layers for EMI control in complex boards

- Separate power and ground planes

- Keep high-speed signals sandwiched between ground layers

Advanced stackups enable high-speed signal transmission with minimal interference.

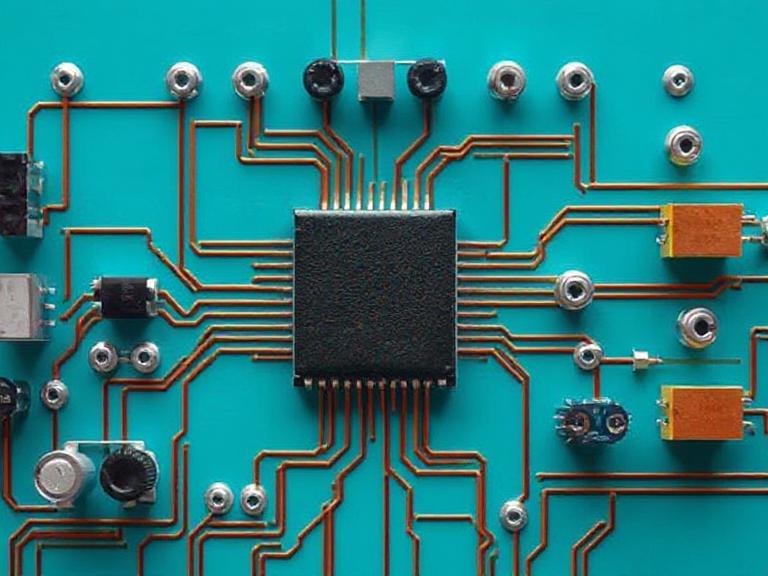

4. Component Placement Is Crucial

Bad placement leads to poor performance and assembly errors

Organizing components logically and efficiently is key to PCB reliability and functionality.

Best practices include:- Group related components into functional blocks

- Keep sensitive analog and noisy digital sections apart

- Align polarized components (e.g., diodes, electrolytic caps) uniformly

- Respect component spacing for heat dissipation and repair access

Wintech supports large size, high-complexity PCBs with precision placement techniques.

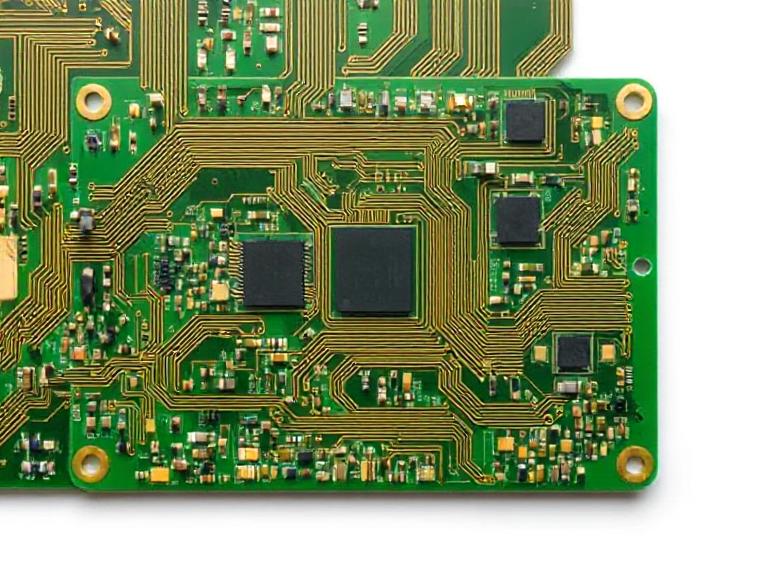

5. Follow Proper Trace Routing Practices

Clean routing ensures signal clarity and electrical performance

Trace design impacts everything from impedance matching to signal integrity.

Tips to optimize routing:- Use the shortest and most direct routing paths

- Avoid 90° trace angles—use 45° for better flow

- Match differential pairs in length and spacing

- Separate analog and digital signal lines

High-difficulty, high-precision layouts are a Wintech specialty, especially for mixed-signal and RF designs.

6. Use Effective Grounding Strategies

Grounding errors are a top cause of PCB failures

Without a solid ground strategy, you risk EMI issues, unstable circuits, and product malfunction.

Best practices:- Use a continuous ground plane under signal lines

- Minimize split ground planes—they cause return path issues

- Isolate noisy grounds (e.g., power) from clean ones (e.g., analog)

Wintech’s engineering team ensures clean ground referencing for all board types.

7. Ensure Signal Integrity

High-speed and analog signals demand accuracy

High-frequency circuits must manage reflection, crosstalk, and delay to maintain signal quality.

Steps to improve signal integrity:- Match impedance of critical signal paths

- Use termination resistors on long lines

- Minimize stubs and via usage on high-speed signals

Signal simulations are part of Wintech’s full turnkey prototyping and layout validation process.

8. Design for Manufacturability (DFM)

Make sure your design can be reliably fabricated and assembled

Even perfect schematics fail if the board can’t be manufactured efficiently.

DFM principles:- Use standard component footprints and spacing

- Avoid placing parts too close to board edges

- Label components clearly on silkscreen

- Design for stencil printing and pick-and-place equipment

Wintech’s NPI and prototyping services help customers identify DFM issues early.

9. Run DRC, DFM, and ERC Checks

Automated rule checking saves time and errors

Before sending your design for manufacturing, always perform:

- DRC (Design Rule Check): Ensures layout follows board house constraints

- DFM (Design for Manufacturability): Verifies assembly feasibility

- ERC (Electrical Rule Check): Checks logical consistency of the circuit

Professional EMS providers like Wintech can assist with these validations using industry-leading software tools.

10. Collaborate with an Experienced PCB Partner

Design success depends on manufacturing partnership

Today’s complex electronic products demand more than just good design—they require manufacturing expertise from concept to delivery.

- PCB Design & Layout

- PCB Manufacturing & Assembly (PCBA, SMT)

- Quick Turn Prototyping

- Metal and Plastic Precision Machining

- Complete Turnkey System Manufacturing

Trusted by top-tier enterprises globally, Wintech is your reliable partner for every stage of electronic product development.

Summary Table: Top 10 PCB Design Rules

| Rule | Description | Why It Matters |

|---|---|---|

| 1. Understand Circuit Requirements | Start with a well-defined schematic | Avoids functional design flaws |

| 2. Choose the Right Material | Select substrates based on performance needs | Affects signal, heat, and reliability |

| 3. Optimize Layer Stackup | Design signal/power/ground layers smartly | Improves EMI and mechanical strength |

| 4. Smart Component Placement | Group logically, respect thermal zones | Simplifies routing and boosts reliability |

| 5. Follow Trace Routing Best Practices | Route cleanly with matching lengths | Maintains signal quality |

| 6. Grounding Strategy | Use continuous, unbroken ground planes | Reduces noise and EMI |

| 7. Signal Integrity | Simulate and control high-speed traces | Ensures data accuracy |

| 8. Design for Manufacturability | Use standard footprints and spacing | Reduces production errors |

| 9. DRC/DFM/ERC Checks | Run automated error checks | Prevents costly mistakes |

| 10. Partner with a Pro | Choose a full-service EMS partner like Wintech | Guarantees success from idea to delivery |