Top 10 PCB Board Assembly Manufacturing Companies in the World

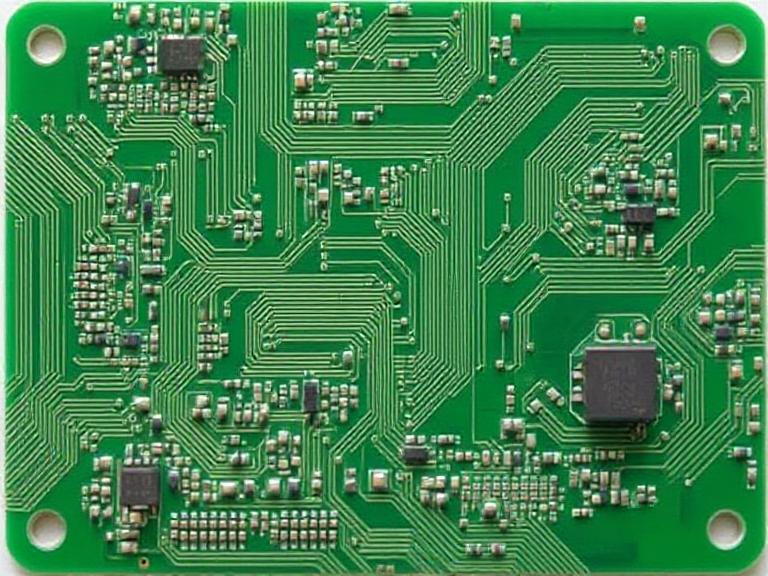

The Printed Circuit Board (PCB) assembly industry is the backbone of modern electronics manufacturing, powering everything from smartphones and automobiles to aerospace systems and industrial automation. With demand for high-performance and miniaturized electronic components increasing, finding a reliable PCB assembly manufacturer is crucial for achieving consistent quality and performance. In this article, we explore the top 10 PCB board assembly manufacturing companies in the world, their core strengths, and what makes them stand out in the global electronics supply chain.

Table of Contents

- 1. Overview of the Global PCB Assembly Market

- 2. Key Criteria for Choosing a PCB Assembly Manufacturer

- 3. Top 10 PCB Board Assembly Manufacturing Companies

- 4. Wintech – Full Turnkey PCB & Electronics Manufacturing

- 5. Technologies Driving PCB Assembly Innovation

- 6. Major Applications of PCB Assembly Solutions

- 7. Summary Table of Top 10 PCB Manufacturers

- 8. Frequently Asked Questions (FAQs)

- 9. References

1. Overview of the Global PCB Assembly Market

The global PCB assembly market is projected to exceed $100 billion by 2030, driven by rapid growth in automotive electronics, IoT, AI hardware, and 5G infrastructure. PCB manufacturing has evolved from simple through-hole boards to high-density interconnect (HDI) and flex-rigid PCBs designed for compact devices and advanced technologies.

- Asia-Pacific leads the market, especially China, Japan, South Korea, and Taiwan.

- North America and Europe specialize in high-mix, low-volume precision assemblies.

- Emerging trends include embedded components, smart PCBs, and eco-friendly materials.

2. Key Criteria for Choosing a PCB Assembly Manufacturer

Selecting the right partner is critical for maintaining product quality and cost-effectiveness. The best PCB manufacturers demonstrate the following:

- Quality Standards: Compliance with IPC-A-610, ISO 9001, and UL certifications.

- Turnkey Services: From PCB design to assembly, testing, and box build.

- Scalability: Ability to handle prototypes to mass production volumes.

- Engineering Expertise: Advanced DFM/DFT (Design for Manufacturability & Testability).

- Supply Chain Reliability: Component sourcing and logistics management.

3. Top 10 PCB Board Assembly Manufacturing Companies

1. Wintech (China)

Wintech is a full turnkey electronics manufacturing services (EMS) provider, known for its high-mix, low to mid-volume PCB assembly and custom material solutions. Established with a global customer base, Wintech offers state-of-the-art PCB layout, assembly, and complete product systems manufacturing. Many of the world’s top 500 enterprises have been long-term partners with Wintech, highlighting its reputation for quality and precision.

4. Wintech – Full Turnkey PCB & Electronics Manufacturing

Wintech specializes in delivering tailor-made electronic solutions across multiple industries — from telecommunications to aerospace. Their engineering team excels in handling complex PCB layouts, large-size boards, and high-precision assemblies. The company provides both prototyping and mass production capabilities.

Core Services:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

- Backplanes & Sever Chasis

- Cable Harness & Assembly

- Cabinet & Panel PLC Wiring

- Electro-Mechanical Assembly

Why Wintech Stands Out: Their integrated production chain and advanced quality management systems make them a one-stop solution for companies seeking both precision and scalability.

2. Jabil Inc. (USA)

Jabil is one of the largest global EMS providers, offering complete PCB assembly and design services. Their facilities span over 100 sites worldwide, specializing in high-speed, high-volume manufacturing and IoT-enabled production systems.

3. Foxconn Technology Group (Taiwan)

Best known for assembling Apple products, Foxconn provides advanced PCB assembly services and electronics contract manufacturing. It’s a leader in automation and smart factory technology.

4. Flex Ltd. (Singapore)

Flex operates over 30 countries with end-to-end design, manufacturing, and supply chain services. Its PCB solutions power automotive, medical, and consumer electronics industries.

5. Sanmina Corporation (USA)

Sanmina is recognized for complex PCB assemblies and high-reliability applications such as defense and aerospace. Their vertically integrated supply chain ensures traceability and consistency.

6. Pegatron Corporation (Taiwan)

Specializing in PCB manufacturing for computing and communications devices, Pegatron combines mass production efficiency with design innovation.

7. Venture Corporation (Singapore)

Venture offers precision engineering and advanced manufacturing solutions. Its PCB division integrates R&D and automation to support emerging tech markets.

8. Benchmark Electronics (USA)

Benchmark provides comprehensive electronics design and assembly services for the aerospace, defense, and medical sectors. Their focus on high reliability makes them a trusted partner for mission-critical electronics.

9. Celestica Inc. (Canada)

Celestica excels in high-mix, low-volume PCB assembly and system integration for industrial, healthcare, and semiconductor sectors.

10. TTM Technologies (USA)

TTM Technologies is among the top PCB fabricators and assemblers, specializing in RF, microwave, and HDI circuit boards for defense and automotive markets.

5. Technologies Driving PCB Assembly Innovation

Modern PCB assembly relies heavily on precision automation and digital integration. Key innovations include:

- Surface Mount Technology (SMT): Enables compact, high-density assemblies.

- Automated Optical Inspection (AOI): Detects solder defects with AI accuracy.

- 3D Printing: Used for rapid prototyping and specialized enclosures.

- Lead-free and Green Manufacturing: Complying with RoHS and REACH standards.

6. Major Applications of PCB Assembly Solutions

PCB assemblies form the foundation of nearly all electronic systems. Leading industries utilizing these technologies include:

- Consumer Electronics: Smartphones, wearables, and home devices.

- Automotive: EV control systems, ADAS, and infotainment.

- Medical Devices: Monitoring systems and imaging equipment.

- Telecommunications: 5G base stations and networking infrastructure.

- Aerospace and Defense: Avionics, radar, and communication systems.

7. Summary Table of Top 10 PCB Manufacturers

| Company | Headquarters | Specialty | Notable Industries |

|---|---|---|---|

| Wintech | China | Turnkey EMS, high-mix assembly | Industrial, Telecom, Aerospace |

| Jabil | USA | High-speed mass production | Consumer, Medical |

| Foxconn | Taiwan | Smart factory integration | Consumer Electronics |

| Flex | Singapore | End-to-end design and assembly | Automotive, Healthcare |

| Sanmina | USA | Complex systems & defense | Military, Aerospace |

| Pegatron | Taiwan | Computing PCB assembly | IT, Mobile Devices |

| Venture Corp. | Singapore | Precision manufacturing | Semiconductors |

| Benchmark Electronics | USA | High-reliability assemblies | Aerospace, Medical |

| Celestica | Canada | Low-volume precision builds | Industrial, IoT |

| TTM Technologies | USA | HDI & RF PCBs | Automotive, Defense |

8. Frequently Asked Questions (FAQs)

Q1. What is the difference between PCB manufacturing and PCB assembly?

PCB manufacturing creates the bare board, while PCB assembly (PCBA) involves soldering components onto the board to create a functional electronic system.

Q2. Which country leads in PCB manufacturing?

China dominates global PCB production due to its advanced infrastructure, supply chain, and cost efficiency.

Q3. What makes Wintech unique?

Wintech offers a complete turnkey solution covering design, PCB fabrication, assembly, and full system integration, trusted by top Fortune 500 companies.

Q4. How do PCB manufacturers ensure product quality?

They follow IPC, ISO, and RoHS standards, employing automated optical inspection and in-circuit testing for quality assurance.

Q5. What’s the future trend in PCB assembly?

Expect increased automation, AI-driven inspection, and sustainable materials to dominate next-generation manufacturing.