How Long Does PCB Assembly Take? Complete Guide, Timeline & Factors

When planning electronic product development, one of the most frequent questions engineers and buyers ask is: How long does PCB assembly take? Understanding PCB assembly timelines helps with scheduling, budgeting, and preparing realistic product launch cycles. In this guide, we break down every stage of PCB assembly, typical lead times, the factors that affect production speed, and how to reduce delays effectively.

Table of Contents

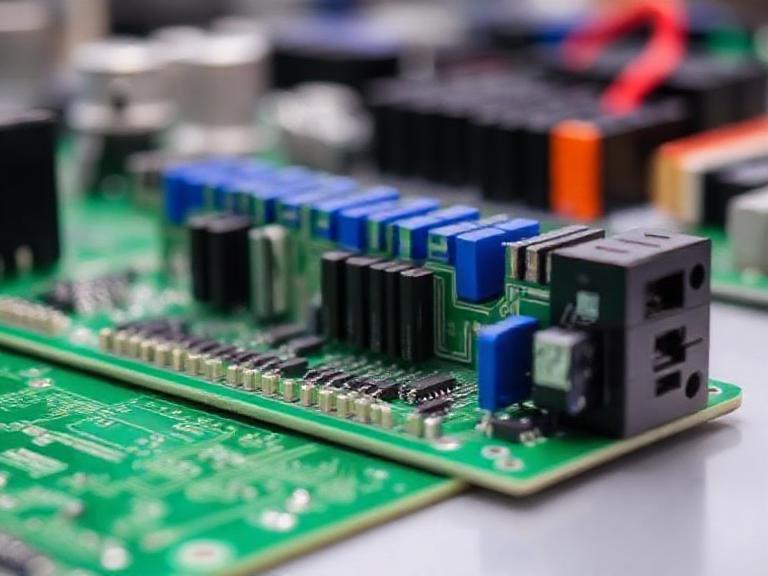

What Is PCB Assembly?

PCB assembly (PCBA) is the process of mounting electronic components onto a printed circuit board. This includes SMT assembly, through-hole soldering, inspection, testing, and final packaging. For OEMs and product developers, PCBA is a crucial step in turning circuit designs into functional hardware.

How Long Does PCB Assembly Take?

The typical timeline for PCB assembly varies widely. On average:

- Prototype PCB assembly: 24 hours – 7 days

- Small to mid-volume production: 1 – 3 weeks

- Mass production: 3 – 6 weeks

The answer to the question “How long does PCB assembly take?” depends on product complexity, parts availability, manufacturing capabilities, and testing requirements. For more advanced boards (high layer count, BGA-heavy, or complex materials), assembly time may be longer.

PCB Assembly Timeline Breakdown

1. PCB Fabrication (3–12 days)

If fabrication and assembly are done together, PCB production is the first stage. Multilayer boards take longer than single-layer boards.

2. Component Sourcing (2 days – several weeks)

Lead times vary significantly depending on component availability. Some chips may have 4–12 week lead times.

3. SMT Assembly (1–5 days)

SMT pick-and-place production is fast for most modern manufacturers.

4. Through-Hole Assembly (1–3 days)

Manual soldering or wave soldering may increase total time if the design has many through-hole components.

5. Inspection & Testing (1–5 days)

- AOI

- ICT

- Functional testing

- X-ray inspection for BGAs

6. Packaging & Delivery (1–3 days)

Once tested, boards are packaged and shipped to the final destination.

Top Factors That Impact PCB Assembly Time

1. Component Availability

The #1 cause of delayed PCB assembly is parts shortages.

2. PCB Complexity

More layers, fine-pitch BGAs, HDI boards, and advanced materials require longer processing times.

3. Order Volume

Prototypes can be produced in 1–3 days, but mass production requires more scheduling and setup.

4. Testing Requirements

Some projects require multiple test cycles, which increases total time.

5. Manufacturer Capability

Factories with advanced automation and turnkey services can deliver significantly faster results.

How to Speed Up PCB Assembly

- Use a manufacturer offering turnkey PCB assembly

- Choose commonly stocked components

- Submit complete documentation: Gerber, BOM, pick-and-place file

- Avoid last-minute engineering changes

- Use an experienced, vertically integrated supplier

Summary Table: PCB Assembly Lead Times

| Project Type | Typical Time | Notes |

|---|---|---|

| Prototype PCB Assembly | 24 hrs – 7 days | Fastest when using turnkey services |

| Low–Mid Volume | 1 – 3 weeks | Standard orders, moderate complexity |

| Mass Production | 3 – 6 weeks | Depends heavily on components & testing |

Company Spotlight: Wintech Electronics Manufacturing

Wintech is a global leader in full turnkey, high-mix, low to mid-volume electronics manufacturing. With decades of experience and long-term cooperation with Fortune 500 companies, Wintech delivers world-class PCB and PCBA solutions.

Why Wintech Stands Out

- Advanced PCB layout for complex, large-size, and high-precision boards

- One-stop service: design → manufacturing → assembly → complete product systems

- Fast prototype and quick-turn PCB assembly options

- Trusted by global enterprises for quality and reliability

Wintech Services

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

For companies needing reliable and efficient manufacturing, Wintech is a partner worth relying on.

Frequently Asked Questions

1. What is the fastest PCB assembly time available?

Some manufacturers offer 24-hour prototype assembly depending on part availability and design complexity.

2. Does turnkey PCB assembly speed up production?

Yes. Turnkey services handle fabrication, assembly, and sourcing—significantly reducing total lead time.

3. Why do components delay PCB assembly?

Shortages or long lead-time chips (MCUs, FPGAs, power ICs) extend timelines by weeks or months.

4. Does design complexity affect how long PCB assembly takes?

Absolutely. More layers, micro-vias, BGAs, and dense routing require additional processing and testing.

5. Can I speed up PCB assembly for urgent orders?

Yes—choose expedited service, use in-stock parts, and ensure complete design documentation.