7 Steps to Make a Circuit Board Design

Designing a Printed Circuit Board (PCB) is a critical process in modern electronics manufacturing. From smartphones to satellites, PCBs are the foundation of virtually every electronic device. A well-designed PCB ensures signal integrity, reliability, and optimal performance. But how do you create a professional circuit board design from start to finish?

This comprehensive guide explores the step-by-step process of making a circuit board design, essential design principles, tools, and professional practices. We will also introduce Wintech — a world-leading PCB design company specializing in high-speed PCB design, SI/PI/EMC analysis, consulting, and training.

Table of Contents

- 1. Understanding PCB Design Overview

- 2. Step 1 — Define the Circuit Concept and Requirements

- 3. Step 2 — Create the Schematic Diagram

- 4. Step 3 — PCB Layout Design

- 5. Step 4 — Routing and Design Optimization

- 6. Step 5 — Simulation and Analysis

- 7. Step 6 — DFM Checking and Gerber Generation

- 8. Step 7 — Prototype Testing and Validation

- 9. About Wintech PCB Design

- 10. Summary Table

- 11. FAQs

- 12. References

Understanding PCB Design Overview

A Printed Circuit Board (PCB) mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from copper sheets. PCB design requires precise engineering and careful planning to ensure performance, reliability, and manufacturability.

Modern PCBs can range from single-layer designs to complex 42-layer high-speed boards used in servers, communication systems, and embedded computing. To create a successful design, engineers follow a structured process from schematic creation to layout and manufacturing.

Step 1 — Define the Circuit Concept and Requirements

The first step in circuit board design is to clearly define the functional requirements and specifications. This includes understanding the device’s purpose, operating conditions, and performance parameters.

Key Requirements to Define:

- Electrical functionality and component selection.

- Board size and mechanical constraints.

- Power consumption and signal speed.

- Number of layers and expected density.

- Environmental conditions (temperature, vibration, humidity).

Defining these parameters ensures your PCB design process starts on a solid foundation. For example, Wintech engineers handle designs with up to 69,000+ pins and 42 layers, demonstrating how advanced specifications influence layout decisions.

Step 2 — Create the Schematic Diagram

The schematic is the electrical blueprint of your circuit. Using software such as Altium Designer, Cadence Allegro, or Mentor Graphics, you draw the interconnections between components using symbols and nets.

Tips for Schematic Design:

- Use standard symbols for clarity.

- Organize circuits logically by function.

- Label power rails and signals consistently.

- Perform an Electrical Rules Check (ERC) to detect connectivity errors.

Once complete, the schematic is converted into a Netlist, which serves as the basis for PCB layout design.

Step 3 — PCB Layout Design

In this stage, components are placed on the PCB according to the schematic. Layout design involves balancing performance, manufacturability, and mechanical requirements. Placement is crucial because it affects routing complexity, thermal management, and signal integrity.

Considerations for Component Placement:

- Place critical components (CPUs, memory, connectors) first.

- Group related components close together.

- Ensure proper spacing for heat dissipation.

- Keep analog and digital sections separate to reduce noise.

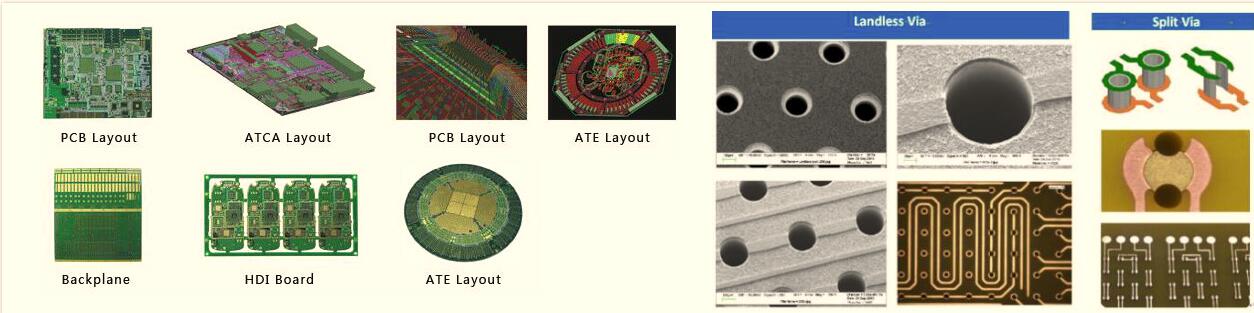

Wintech’s engineers use independently developed software tools to enhance layout efficiency and accuracy, delivering over 8000+ PCB design projects per year.

Step 4 — Routing and Design Optimization

Routing defines the copper traces that connect components on the board. This step is critical for maintaining electrical performance and manufacturability.

Routing Guidelines:

- Maintain minimum line width and spacing (e.g., 2.4 mils at Wintech’s precision standards).

- Use differential pairs for high-speed signals.

- Keep trace lengths balanced for clock and data signals.

- Minimize via count to reduce signal loss.

High-speed designs may involve signal frequencies exceeding 10GHz, such as Intel Xeon server boards and Broadcom Ethernet switches — all within Wintech’s portfolio of expertise.

Step 5 — Simulation and Analysis

Before manufacturing, simulation helps identify potential issues related to Signal Integrity (SI), Power Integrity (PI), and Electromagnetic Compatibility (EMC). Simulation ensures the design performs reliably under real-world conditions.

Simulation Techniques:

- Time-domain and frequency-domain analysis for signal integrity.

- Thermal analysis for heat management.

- EMI/EMC testing simulations for compliance with industry standards.

Wintech’s dedicated SI/PI/EMC team provides comprehensive analysis services to verify design stability for clients like Intel, Cisco, Huawei, and TI.

Step 6 — DFM Checking and Gerber Generation

After the layout and simulation are finalized, the next step is Design for Manufacturability (DFM) checking. This ensures that the design complies with manufacturing tolerances and assembly constraints.

DFM Checklist:

- Check minimum trace width, spacing, and drill sizes.

- Validate solder mask and silkscreen placement.

- Ensure component footprints match physical parts.

Once approved, Gerber files — the universal manufacturing format — are generated for production. Wintech’s “PCB Design Total Solution” includes netlist import, DFM checking, QA & review, and Gerber output.

Step 7 — Prototype Testing and Validation

Before mass production, prototypes undergo functional testing to validate the electrical and mechanical design. Testing ensures that the PCB meets all design specifications and performs reliably in real-world conditions.

Testing Methods Include:

- Continuity and insulation resistance testing.

- Power-on functional verification.

- Thermal cycling and vibration tests.

Feedback from this phase is used to make any necessary design revisions before moving into full-scale production.

About Wintech PCB Design

Wintech has been a trusted name in PCB design since 1995. Specializing in high-speed PCB design, SI/PI/EMC analysis, training, and consulting, Wintech serves over 5,000 global clients. The company is recognized as China’s leading PCB design center with a team of 200+ professional engineers.

Core Strengths:

- 200+ full-time engineers and 8000+ design projects annually.

- Recognized by leading tech companies like Intel, Cisco, Huawei, Lenovo, and Texas Instruments.

- Expertise in DDR4 and 25Gbps+ backplane signal design and simulation.

- Comprehensive service: from footprint creation to QA, DFM, and Gerber output.

Advantages:

- Experienced experts delivering high-quality designs.

- Large, customer-focused engineering team.

- Independently developed software to improve efficiency.

- Constant innovation to keep up with the latest technologies.

Wintech’s PCB layout solutions cover a wide range of applications including backplane, high-speed PCB design, A/D PCB design, HDI, buried resistance/capacitance, flex, rigid-flex boards, and ATE. The company’s designs power products in IT, telecommunications, medical, and consumer electronics.

Summary Table

| Step | Key Action | Outcome |

|---|---|---|

| 1. Define Requirements | Gather specifications and constraints | Clear design roadmap |

| 2. Create Schematic | Draw circuit connections | Electrical blueprint |

| 3. Layout Design | Place components on the board | Optimized structure |

| 4. Routing | Connect traces and vias | Functional electrical paths |

| 5. Simulation | Run SI/PI/EMC analysis | Reliable design validation |

| 6. DFM & Gerber | Manufacturing checks and file output | Production-ready files |

| 7. Testing | Prototype and validate | Final design approval |

FAQs — Circuit Board Design

1. What software is used for PCB design?

Common tools include Altium Designer, Cadence Allegro, Mentor Graphics PADS, and KiCad. Wintech uses professional tools combined with proprietary software for maximum efficiency.

2. How many layers can a PCB have?

Depending on the complexity, PCBs can range from single-layer to multi-layer boards exceeding 40 layers. Wintech designs up to 42-layer high-density boards.

3. What industries use Wintech PCB design services?

Wintech serves IT, communications, medical, consumer electronics, and computer industries worldwide.

4. Does Wintech offer training and consulting?

Yes. Wintech provides professional training and consulting services to help organizations improve in-house PCB design capabilities.