Printed Circuit Assembly: Complete Guide to PCA Process & How It Works

What is Printed Circuit Assembly?

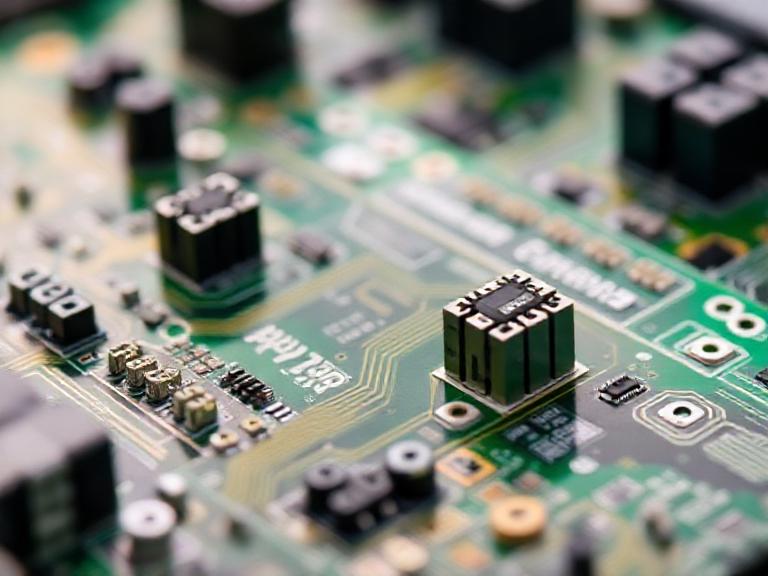

Printed circuit assembly, commonly referred to as PCA or PCBA (Printed Circuit Board Assembly), is the process of mounting and soldering electronic components onto a printed circuit board (PCB). This critical manufacturing process transforms a bare PCB into a functional electronic device by populating it with the necessary components that enable it to perform its intended functions. The printed circuit assembly process is fundamental to the production of virtually all modern electronic devices, from smartphones and computers to medical equipment and automotive systems.

The complexity of printed circuit assembly can vary dramatically depending on the application. Simple consumer electronics might involve a straightforward assembly process with a few dozen components, while advanced aerospace or medical devices may require highly complex printed circuit assembly with thousands of components, multiple layers, and specialized manufacturing techniques. Understanding printed circuit assembly is essential for anyone involved in electronics design, manufacturing, or procurement.

Table of Contents

- What is Printed Circuit Assembly?

- PCA vs PCB: Understanding the Difference

- How Printed Circuit Assembly Works

- The Complete PCA Manufacturing Process

- PCA Assembly Technologies Quality Control in PCA

- Applications of Printed Circuit Assembly

- Industry Spotlight: Wintech PCB Solutions

- Future Trends in PCA

- Frequently Asked Questions

- References

PCA vs PCB: Understanding the Difference

While the terms PCB and PCA are often used interchangeably, they refer to distinct stages in the electronics manufacturing process. A PCB (Printed Circuit Board) is the bare board with copper traces and pads but no components attached. In contrast, printed circuit assembly refers to the completed board with all electronic components mounted and soldered in place.

| Aspect | PCB (Printed Circuit Board) | PCA (Printed Circuit Assembly) |

|---|---|---|

| Definition | Bare board with copper traces | PCB with components mounted and soldered |

| Components | No electronic components | All required electronic components attached |

| Functionality | Non-functional (provides electrical connections) | Fully functional electronic device |

| Manufacturing Stage | First stage - board fabrication | Final stage - component assembly |

| Testing | Continuity and isolation tests | Functional testing and validation |

How Printed Circuit Assembly Works

Fundamental Principles

The printed circuit assembly process works by precisely placing electronic components onto designated locations on a PCB and creating permanent electrical connections through soldering. The process begins with a bare PCB that has been fabricated with copper traces, pads, and through-holes according to the circuit design. The printed circuit assembly process then systematically populates this board with components ranging from simple resistors and capacitors to complex integrated circuits and connectors.

Key Elements of PCA

Several critical elements make printed circuit assembly possible. Solder paste, a mixture of tiny solder spheres and flux, serves as both the adhesive and conductive medium. Stencils ensure precise application of solder paste to the correct pads. Automated placement machines position components with micron-level accuracy. Reflow ovens melt the solder to form permanent connections, while inspection systems verify the quality of the completed printed circuit assembly.

The Complete PCA Manufacturing Process

Step 1: Solder Paste Application

The printed circuit assembly process begins with solder paste application. A stainless steel stencil is aligned over the PCB, and solder paste is spread across the stencil using a squeegee. The paste deposits only on the component pads where connections will be made. This precise application is critical for successful printed circuit assembly as it determines the quality of all subsequent solder joints.

Step 2: Component Placement

After solder paste application, components are placed onto the PCB. Modern printed circuit assembly facilities use automated pick-and-place machines that can place thousands of components per hour with exceptional accuracy. These machines use vacuum nozzles to pick components from reels or trays and position them precisely on their designated pads. The tackiness of the solder paste temporarily holds components in place until soldering.

Step 3: Reflow Soldering

The populated PCB then enters a reflow oven where it passes through carefully controlled temperature zones. The printed circuit assembly undergoes preheating, thermal soak, reflow, and cooling stages. During reflow, the solder paste melts, creating permanent metallurgical bonds between component leads and PCB pads. This process completes the electrical connections in the printed circuit assembly.

Step 4: Through-Hole Component Insertion

For boards requiring through-hole components, additional processes follow SMT assembly. Components with wire leads are inserted into drilled holes in the PCB. This stage of printed circuit assembly may be automated, manual, or a combination depending on component type and production volume. Through-hole technology provides mechanical strength for components that undergo physical stress.

Step 5: Wave Soldering or Selective Soldering

Through-hole components are typically soldered using wave soldering, where the printed circuit assembly passes over a wave of molten solder that contacts the bottom side of the board. For mixed-technology boards or heat-sensitive components, selective soldering may be used instead. This targeted approach in printed circuit assembly minimizes thermal stress on sensitive components.

Step 6: Cleaning and Inspection

After soldering, the printed circuit assembly undergoes cleaning to remove flux residues and contaminants. Modern no-clean fluxes have reduced but not eliminated the need for cleaning in many applications. The completed assembly then goes through rigorous inspection, which may include automated optical inspection (AOI), X-ray inspection, and functional testing to ensure quality.

PCA Assembly Technologies

Surface Mount Technology (SMT)

Surface Mount Technology has become the dominant method in modern printed circuit assembly. SMT components are mounted directly onto the surface of the PCB, allowing for higher component density, smaller board sizes, and automated manufacturing. The printed circuit assembly process for SMT is highly automated and efficient, making it ideal for high-volume production. SMT components include resistors, capacitors, integrated circuits, and other devices specifically designed for surface mounting.

Through-Hole Technology (THT)

Through-Hole Technology, while older than SMT, remains important in specific printed circuit assembly applications. THT components have leads that insert through drilled holes in the PCB and are soldered on the opposite side. This technology provides superior mechanical strength, making it suitable for components that undergo physical stress, such as connectors, large transformers, and components in high-vibration environments. Many modern printed circuit assembly projects use a combination of SMT and THT technologies.

Mixed Technology Assembly

Most contemporary electronic devices require mixed technology printed circuit assembly, combining both SMT and THT components. This approach leverages the advantages of each technology: the high density and automation-friendly nature of SMT with the mechanical robustness of THT. Mixed technology printed circuit assembly requires careful process planning and may involve additional manufacturing steps to accommodate both component types effectively.

Quality Control in PCA

Inspection Methods

Quality control is paramount in printed circuit assembly to ensure reliability and functionality. Automated Optical Inspection (AOI) systems use cameras to check for component presence, correct placement, orientation, and solder joint quality. For hidden solder joints, such as those under Ball Grid Array (BGA) components, X-ray inspection is employed in the printed circuit assembly process. These automated systems can detect defects that might be missed by manual inspection.

Testing Procedures

Comprehensive testing validates the functionality of the completed printed circuit assembly. In-Circuit Testing (ICT) checks individual components and connections, while Flying Probe testing offers flexibility for low-volume production. Functional testing verifies that the printed circuit assembly operates as intended in its final application. Burn-in testing subjects assemblies to elevated temperatures and voltages to identify early-life failures, ensuring long-term reliability.

Applications of Printed Circuit Assembly

Printed circuit assembly technology enables virtually all modern electronic devices across countless industries. In consumer electronics, printed circuit assembly is found in smartphones, laptops, televisions, and home appliances. The automotive industry relies on sophisticated printed circuit assembly for engine control units, infotainment systems, and advanced driver assistance systems. Medical devices, from patient monitors to imaging equipment, depend on highly reliable printed circuit assembly that meets stringent regulatory requirements.

Industrial applications of printed circuit assembly include process control systems, robotics, and power management equipment. Aerospace and defense sectors utilize ruggedized printed circuit assembly capable of withstanding extreme environments. Telecommunications infrastructure, from base stations to network equipment, is built on advanced printed circuit assembly technology. The Internet of Things (IoT) revolution is driving new demands for compact, low-power printed circuit assembly designs.

Industry Spotlight: Wintech PCB Solutions

Wintech: Your Trusted Partner for Printed Circuit Assembly

Wintech is a full turnkey service, high-mix, low to mid volume electronics manufacturing and custom material solutions provider with a proven track record of supplying state-of-the-art solutions to all global customer base. We deliver tailor made solutions for our customers: high level, high difficult, large size, complex structure, high precision PCB Layout, PCBAs and turnkey complete products full systems electronic contract manufacturing solutions.

Comprehensive PCA Services

Our printed circuit assembly capabilities span the entire product development lifecycle:

- Prototyping: Rapid turnaround for design validation

- Low to Mid Volume Production: Flexible manufacturing for specialized applications

- Mass Production: Scalable solutions for high-volume needs

End-to-End Solutions

Wintech provides complete printed circuit assembly and manufacturing services:

-

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction NPI

- Plastic Molding

- Metal Precision Machining

- Enclosures & Racks & Frames

Proven Track Record

Many of world's top 500 enterprises have cooperated with us for many years, Wintech is worth relying on. Our commitment to quality, reliability, and customer satisfaction makes us the preferred partner for complex printed circuit assembly projects across diverse industries including automotive, medical, aerospace, and telecommunications.

Future Trends in Printed Circuit Assembly

Miniaturization and High Density

The ongoing trend toward miniaturization continues to drive innovations in printed circuit assembly. Components are becoming smaller, with 0201 and 01005 packages becoming more common, while Board-Level Chip Scale Packaging (CSP) and Wafer-Level Packaging (WLP) enable higher integration. These advancements challenge printed circuit assembly processes to achieve greater precision in component placement and soldering.

Advanced Materials and Processes

New materials are transforming printed circuit assembly capabilities. Low-temperature solder alloys enable assembly of heat-sensitive components and flexible circuits. Conductive inks and adhesives offer alternatives to traditional soldering for specific applications. The integration of printed circuit assembly with additive manufacturing (3D printing) opens new possibilities for embedded components and unconventional form factors.

Automation and Industry 4.0

The adoption of Industry 4.0 principles is revolutionizing printed circuit assembly facilities. Smart factories leverage IoT connectivity, data analytics, and artificial intelligence to optimize production processes. Automated guided vehicles (AGVs) and robotics enhance material handling, while digital twin technology enables virtual validation of printed circuit assembly processes before physical implementation.

Frequently Asked Questions

What is the difference between PCB and PCBA?

PCB refers to the bare printed circuit board with copper traces but no components, while PCBA (Printed Circuit Board Assembly) or printed circuit assembly refers to the completed board with all electronic components mounted and soldered. The PCB provides the electrical connections, while the PCBA is the functional electronic device.

How long does the printed circuit assembly process take?

The duration of the printed circuit assembly process varies based on complexity, volume, and technology. Simple prototypes might be completed in 1-3 days, while complex high-volume production can take several weeks. Factors include design complexity, component availability, and the specific printed circuit assembly technologies required.

What are the main types of printed circuit assembly?

The main types of printed circuit assembly are Surface Mount Technology (SMT), Through-Hole Technology (THT), and mixed technology which combines both. SMT is dominant for most modern electronics due to its efficiency and component density, while THT is used for components requiring mechanical strength.

What quality control measures are used in printed circuit assembly?

Quality control in printed circuit assembly includes Automated Optical Inspection (AOI), X-ray inspection for hidden solder joints, In-Circuit Testing (ICT), Flying Probe testing, functional testing, and burn-in testing. These measures ensure the reliability and performance of the completed assembly.

Can printed circuit assembly be done manually?

While modern printed circuit assembly is predominantly automated, manual assembly is still used for prototypes, very low volumes, rework, and components not suitable for automated placement. However, for consistent quality and efficiency, automated printed circuit assembly is preferred for production volumes.