Differences Between PCB Fabrication and PCB Assembly (2025 Guide)

In the electronics manufacturing world, two critical processes are often confused: PCB fabrication and PCB assembly. While they are closely related, each serves a distinct role in bringing electronic products to life. This guide explains the differences, processes, and benefits of both.Top 7 PCB Fabrication & Assembly Manufacturers in the World (2025)

Table of Contents

- What is PCB Fabrication?

- What is PCB Assembly?

- Key Differences Between PCB Fab and Assembly

- Step-by-Step PCB Fabrication Process

- Step-by-Step PCB Assembly Process

- Why Both PCB Fab and Assembly Matter

- Applications in Different Industries

- Challenges in PCB Fab vs. Assembly

- Wintech: Comprehensive PCB Fab & Assembly Solutions

- Summary Table of Differences

- References

What is PCB Fabrication?

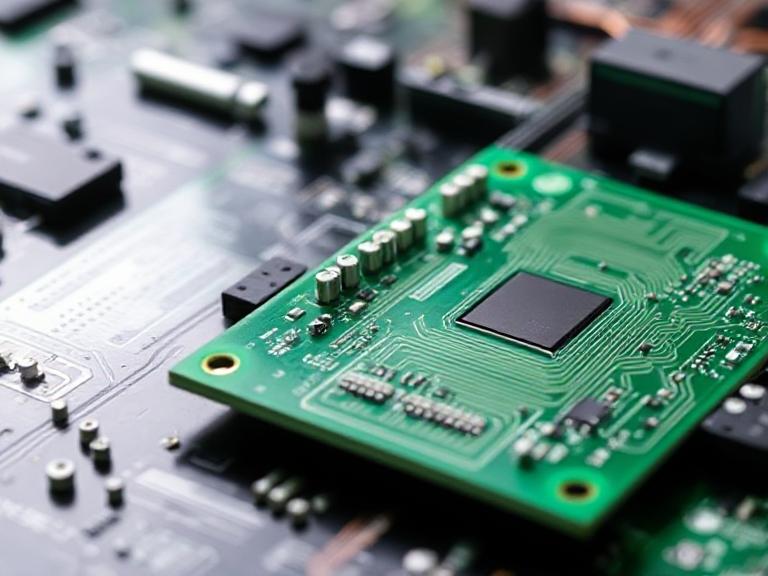

PCB fabrication refers to the process of manufacturing the physical bare printed circuit board (PCB) itself, without any electronic components mounted. It involves turning a circuit design into a functional substrate ready for assembly.

Main features of PCB fabrication include:

- Layer buildup of copper and dielectric materials.

- Etching copper pathways for circuits.

- Drilling holes and vias for connectivity.

- Applying solder mask and silkscreen printing.

What is PCB Assembly?

PCB assembly (PCBA) is the process of mounting electronic components (resistors, capacitors, ICs, connectors, etc.) onto a fabricated PCB to create a fully functional electronic circuit board.

Main features of PCB assembly include:

- Component placement (manual or automated).

- Soldering methods like reflow soldering or wave soldering.

- Inspection and testing for functionality.

- Final cleaning and packaging for delivery.

Key Differences Between PCB Fab and Assembly

Though interconnected, PCB fabrication and assembly are distinct processes:

- PCB Fabrication = Making the bare board (structure).

- PCB Assembly = Adding components (functionality).

Comparison at a glance:

- Focus: Fabrication builds the board; Assembly makes it work.

- Materials: Fabrication uses copper, laminates, epoxy; Assembly uses electronic components.

- Output: Fabrication yields a PCB; Assembly yields a PCBA.

Step-by-Step PCB Fabrication Process

- Design and Layout from CAD files (Gerber data).

- Material preparation (laminates and copper sheets).

- Photoresist application and imaging.

- Copper etching to form circuits.

- Drilling holes and vias.

- Plating and copper deposition.

- Solder mask application.

- Silkscreen printing for labeling.

- Surface finishing (ENIG, HASL, OSP, etc.).

Step-by-Step PCB Assembly Process

- Solder paste application to pads.

- Component placement via pick-and-place machines.

- Reflow soldering for SMT components.

- Through-hole component insertion (if required).

- Wave soldering or hand soldering for through-hole parts.

- Automated Optical Inspection (AOI).

- Electrical testing (ICT, functional tests).

- Final cleaning, coating, and packaging.

Why Both PCB Fab and Assembly Matter

Without fabrication, there is no physical substrate; without assembly, the board cannot function. Together, they form the foundation of modern electronics, from smartphones to aerospace control systems.

Applications in Different Industries

- Consumer Electronics: Smartphones, laptops, wearables.

- Automotive: ADAS, EV power systems.

- Medical Devices: Imaging, diagnostic tools.

- Industrial: Robotics, IoT, automation.

- Aerospace & Defense: Navigation and radar systems.

Challenges in PCB Fab vs. Assembly

- PCB Fabrication Challenges: Miniaturization, HDI (High Density Interconnect), thermal management.

- PCB Assembly Challenges: Component shortages, solder joint reliability, lead-free compliance.

Wintech: Comprehensive PCB Fab & Assembly Solutions

Wintech is a full turnkey service provider, delivering high-mix, low to mid-volume electronics manufacturing and custom material solutions. Trusted by many Fortune 500 companies, Wintech specializes in:

- PCB Design & Layout

- PCB Manufacturing

- PCB Assembly & PCBA SMT

- Quick Turn Fast PCB Prototype Assembly

- New Product Introduction (NPI)

- Plastic Molding & Metal Precision Machining

By integrating both PCB fabrication and assembly, Wintech ensures seamless quality, cost efficiency, and fast turnaround for global customers.

Summary Table of Differences

| Aspect | PCB Fabrication | PCB Assembly |

|---|---|---|

| Definition | Manufacturing of the bare circuit board | Mounting components on fabricated boards |

| Materials | Copper, laminates, solder mask | ICs, resistors, capacitors, connectors |

| Output | PCB | PCBA |

| Techniques | Etching, drilling, plating | Pick-and-place, reflow, wave soldering |

| End Use | Provides structure | Provides functionality |