7 Types of Circuit Boards: An Overview for 2025

Table of Contents

- Introduction: The Importance of Circuit Boards in Modern Electronics

- Understanding Circuit Boards: Definition and Components

-

Types of Circuit Boards

- 3.1 Single-Sided PCBs

- 3.2 Double-Sided PCBs

- 3.3 Multilayer PCBs

- 3.4 Rigid PCBs

- 3.5 Flexible PCBs

- 3.6 Rigid-Flex PCBs

- 3.7 High-Frequency PCBs

- Applications of Different Types of Circuit Boards

- Wintech: A Reliable Circuit Board Manufacturer

-

Common FAQs About Circuit Boards

- 6.1 What is the difference between single-sided and multilayer PCBs?

- 6.2 What industries use flexible PCBs?

- 6.3 What are turnkey PCB solutions?

- Conclusion: Selecting the Right Circuit Board for Your Needs

Introduction: The Importance of Circuit Boards in Modern Electronics

Circuit boards are the backbone of modern electronic devices, playing a crucial role in connecting and controlling components in everything from smartphones to industrial machinery. They provide a structured and compact way to design electronics while ensuring reliability and efficiency.

The advancement of technology has given rise to various types of circuit boards tailored to meet specific needs in industries such as telecommunications, automotive, healthcare, and consumer electronics. Understanding the types of circuit boards available is essential for selecting the right one for your project or application.

Understanding Circuit Boards: Definition and Components

A circuit board, often referred to as a printed circuit board (PCB), is a platform used to mechanically support and electrically connect electronic components. Common components of a PCB include:

- Substrate: The base material providing structural support.

- Copper Traces: Conductive pathways for electrical signals.

- Solder Mask: A protective layer covering copper traces.

- Silkscreen: Used for labeling and adding symbols.

Depending on the design and functionality, circuit boards can range from simple single-layer boards to complex multilayer boards.

Types of Circuit Boards

3.1 Single-Sided PCBs

Single-sided PCBs have one layer of conductive material and are best suited for simple and low-cost applications like calculators and radios.

Features:

- One conductive layer.

- Ideal for low-density designs.

- Cost-effective and easy to produce.

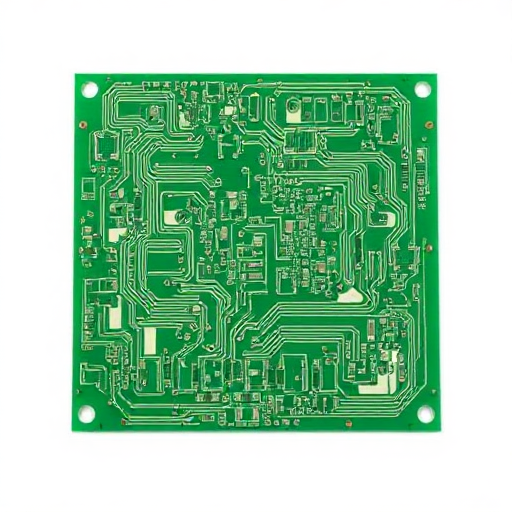

3.2 Double-Sided PCBs

Double-sided PCBs have conductive layers on both sides, allowing components to be mounted on both the top and bottom.

Features:

- Increased complexity compared to single-sided PCBs.

- Enhanced circuit density.

- Common in power supplies and automotive dashboards.

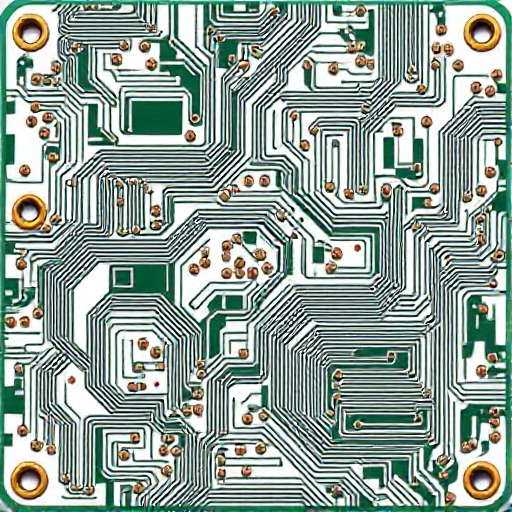

3.3 Multilayer PCBs

Multilayer PCBs feature three or more conductive layers sandwiched between insulating layers. They are used in advanced applications requiring high performance.

Features:

- High-density connections.

- Compact design for complex electronics.

- Widely used in telecommunications and aerospace.

3.4 Rigid PCBs

Rigid PCBs are made from a solid substrate material that prevents the board from bending.

Features:

- Durable and reliable.

- Used in applications where flexibility is not required.

- Common in desktop computers and servers.

3.5 Flexible PCBs

Flexible PCBs are made from bendable materials like polyimide, allowing them to conform to different shapes.

Features:

- Lightweight and versatile.

- Suitable for compact and wearable devices.

- Found in medical devices and flexible displays.

3.6 Rigid-Flex PCBs

Rigid-Flex PCBs combine the benefits of rigid and flexible PCBs, providing a hybrid solution.

Features:

- Versatile and space-saving.

- Improved signal integrity.

- Used in smartphones and aerospace equipment.

3.7 High-Frequency PCBs

High-frequency PCBs are designed for high-speed communication systems, supporting signals above 1GHz.

Features:

- Superior signal integrity.

- Low dielectric loss.

- Used in RF and microwave communication systems.

Applications of Different Types of Circuit Boards

- Consumer Electronics: Smartphones, televisions, and gaming consoles.

- Medical Devices: MRI machines, heart monitors, and diagnostic equipment.

- Automotive: Engine control systems, infotainment, and safety systems.

- Aerospace: Navigation systems, communication devices, and control panels.

- Telecommunications: Routers, switches, and satellite communication systems.

Wintech: A Reliable Circuit Board Manufacturer

Wintech is a leading provider of turnkey circuit board solutions, specializing in high-mix, low-to-mid volume electronics manufacturing. With a focus on delivering state-of-the-art solutions, Wintech serves a global customer base, including some of the world’s top 500 enterprises.

Key Services Provided by Wintech:

- Plastic Molding: High-quality, durable plastic components for PCBs.

- Metal Precision Machining: Custom machining for high-precision parts.

- Cable Harness & Assembly: Tailor-made cable and wiring solutions.

- Turnkey Manufacturing Solutions: From prototyping to mass production.

Why Choose Wintech?

- Expertise in handling high-level, complex PCBs.

- Proven track record with top-tier clients.

- Comprehensive support from design to delivery.

Common FAQs About Circuit Boards

6.1 What is the difference between single-sided and multilayer PCBs?

Single-sided PCBs have only one conductive layer, while multilayer PCBs feature multiple conductive layers separated by insulating layers. Multilayer PCBs are suitable for more complex applications due to their higher circuit density.

6.2 What industries use flexible PCBs?

Flexible PCBs are commonly used in industries like:

- Medical devices (wearables and diagnostic tools).

- Consumer electronics (smartphones and foldable devices).

- Automotive (flexible lighting systems).

6.3 What are turnkey PCB solutions?

Turnkey PCB solutions refer to comprehensive services where manufacturers handle all aspects of PCB production, including design, prototyping, assembly, testing, and delivery. Wintech is a trusted provider of turnkey PCB solutions.

Conclusion: Selecting the Right Circuit Board for Your Needs

Circuit boards are the foundation of modern electronics, and selecting the right type is essential for achieving optimal performance and reliability. Whether you need a single-sided PCB for a simple project or a multilayer, high-frequency PCB for advanced applications, understanding the different types and their applications is crucial.

Wintech’s expertise in PCB manufacturing and turnkey solutions makes it a reliable partner for businesses across industries. From design to mass production, Wintech ensures top-notch quality and performance, meeting the demands of even the most complex projects.