9 Main Components of a PCB: What You Need to Know

Table of Contents

- Introduction: What Is a PCB?

- The Main Layers of a PCB

- Primary Components Found on a PCB

- Advanced and Optional Components

- Wintech: Your Turnkey PCB Manufacturing Partner

- Why These Components Matter

- Summary Table

- References

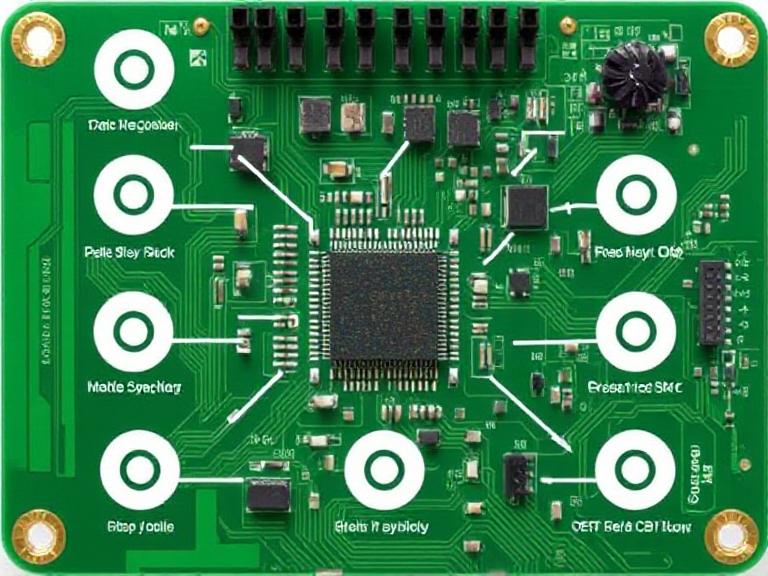

Introduction: What Is a PCB?

A Printed Circuit Board (PCB) is the backbone of modern electronic devices. It mechanically supports and electrically connects electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

Understanding the main components of a PCB helps engineers, designers, and product developers optimize performance, reliability, and manufacturability. Whether you're designing a prototype or scaling to production, knowing the structure and parts of a PCB is essential.

The Main Layers of a PCB

Most PCBs are built in multiple layers, and each serves a distinct purpose. Here are the key ones:

- Substrate (Base Material): The core layer of the PCB, typically made of FR4 (fiberglass), providing rigidity and insulation.

- Copper Layer: A thin layer of copper foil laminated onto the board, forming the conductive paths or traces.

- Solder Mask: A protective layer applied over the copper to prevent oxidation and bridge formation. It gives the PCB its green (or other color) appearance.

- Silkscreen: Used to print component labels, logos, or other identifiers for assembly and troubleshooting.

Primary Components Found on a PCB

PCBs host a variety of electronic components that enable functionality. Here are the most common:

1. Resistors

- Used to limit electrical current flow and adjust signal levels.

- Marked with colored bands indicating resistance value.

2. Capacitors

- Store and release electrical energy.

- Used for filtering, power conditioning, and signal coupling.

3. Inductors

- Store energy in a magnetic field.

- Used in power supplies and radio frequency applications.

4. Diodes

- Allow current to flow in only one direction.

- Protect circuits from reverse voltage damage.

5. Transistors

- Act as amplifiers or switches.

- Found in nearly all logic and analog circuits.

6. Integrated Circuits (ICs)

- Miniaturized electronic circuits embedded into a chip.

- Can include microcontrollers, amplifiers, memory, and processors.

7. Connectors

- Provide electrical interfaces between PCBs and external devices.

- Examples include USB, HDMI, or custom headers.

8. Switches and Buttons

- Allow manual user input or control.

- Come in various forms such as tact switches, DIP switches, and toggles.

9. Crystals and Oscillators

- Provide timing references for microcontrollers and CPUs.

- Essential for synchronous operation in digital circuits.

Advanced and Optional Components

For high-performance or specialized applications, PCBs may also include:

- Heat Sinks: Dissipate excess heat from high-power components.

- FPGAs: Programmable chips for custom digital logic.

- Shielding: Metal cans or coatings to block electromagnetic interference (EMI).

- Sensors: For detecting temperature, humidity, motion, etc.

Wintech: Your Turnkey PCB Manufacturing Partner

Wintech is a globally trusted electronics manufacturing provider, offering full turnkey services in:

- PCB Design & Layout – High-level, high-precision custom layouts for complex and large-scale projects.

- PCB Manufacturing – From low to mid volume to high-mix mass production with strict quality control.

- PCB Assembly & PCBA SMT – Complete SMT and through-hole assembly capabilities.

- Quick Turn PCB Prototyping – Fast turnaround for proof-of-concept and pre-production runs.

- New Product Introduction (NPI) – From ideation to final product, Wintech supports you at every step.

Many of the world’s top 500 enterprises trust Wintech for complex structures, tight tolerances, and challenging layouts. Whether you're developing a medical device, industrial controller, or aerospace system, Wintech’s experience and technology make them a reliable partner.

Why These Components Matter

1. System Performance

- Each component contributes to system speed, power efficiency, and reliability.

2. Signal Integrity

- Improper layout or component mismatch can lead to noise, loss, or even failure.

3. Manufacturability

- Knowing which components go where ensures correct soldering, testing, and final product quality.

4. Cost Optimization

- Component selection impacts total BOM cost, yield rate, and long-term maintenance.

Summary Table

| Component | Function |

|---|---|

| Resistor | Limits current, adjusts voltage |

| Capacitor | Stores/releases electrical energy |

| Inductor | Stores energy in magnetic field |

| Diode | Blocks reverse current flow |

| Transistor | Acts as switch or amplifier |

| IC | Performs logic and processing |

| Connector | Interface to other devices |

| Oscillator | Generates timing signals |