Industrial Medicine PCB Requirements: Key Standards & Manufacturing Insights

Table of Contents

- Introduction

- Importance of PCBs in Industrial Medicine

- Key PCB Requirements for Medical and Industrial Devices

- Material Considerations

- Design & Layout Specifics

- Assembly and Prototyping Requirements

- Compliance, Testing, and Quality Control

- Why Choose Wintech for Industrial Medicine PCBs

- Summary Table

Introduction

Printed Circuit Boards (PCBs) form the technological backbone of countless industrial and medical devices, from life-saving diagnostic tools to industrial robotic systems. These highly specialized electronics demand precision, reliability, and absolute compliance with safety and performance standards. In this article, we outline the critical requirements for PCBs used in industrial medical applications and introduce Wintech—a trusted turnkey electronics manufacturing partner serving the world’s top enterprises.

Importance of PCBs in Industrial Medicine

In industrial medicine, PCBs enable accurate signal processing, data transmission, and power delivery in complex environments. Devices such as:

- Patient monitoring systems

- Infusion pumps

- MRI and CT scanners

- Robotic surgical tools

- Diagnostic imaging equipment

… all depend on high-performance PCBs that can operate reliably under stress, heat, vibration, and continuous usage.

Key PCB Requirements for Medical and Industrial Devices

1. Reliability & Longevity

- High Mean Time Between Failures (MTBF)

- Must endure continuous operation with minimal downtime

- Essential for patient safety and process accuracy

2. Signal Integrity

- Critical for imaging and monitoring equipment

- Use of impedance-controlled traces to prevent signal distortion

3. High-Density Interconnect (HDI)

- Required for complex medical device miniaturization

- Supports high I/O functions in small form factors

4. Multi-Layer Construction

- Medical PCBs often use 4 to 12 layers, or more

- Enables separation of power, ground, and signal planes

5. Safety and Redundancy

- Incorporates fail-safes and redundant circuitry

- Includes patient-isolation circuitry to prevent electrical hazards

Material Considerations

The choice of substrate and insulation materials significantly impacts thermal stability, biocompatibility, and mechanical resilience. Essential materials include:

- FR-4: Standard for general applications

- Polyimide: High heat resistance and flexibility

- Ceramics (e.g., Alumina): Excellent for thermal dissipation

- Rogers and Teflon: Superior high-frequency performance

Industrial medicine applications often call for RoHS and REACH compliant materials to meet global environmental regulations.

Design & Layout Specifics

PCB Design for Medical Compliance

- EMC shielding and grounding considerations

- Minimized electromagnetic interference (EMI)

- Design for thermal regulation and airflow

Wintech’s PCB Design Capabilities:

- High-level, high-difficulty layout for large, complex boards

- Advanced CAD/CAM support for custom shapes and multilayer boards

- Support for both rigid and flex-rigid board designs

Assembly and Prototyping Requirements

Medical PCB assembly must be handled with stringent cleanliness and ESD protection standards.

Wintech’s Turnkey Services Include:

- PCB Assembly & PCBA SMT: Surface mount and through-hole technology

- Fast PCB Prototyping: Rapid iteration for new product development

- New Product Introduction (NPI): From concept to pre-production

- Plastic Molding & Metal Machining: For complete enclosure and hardware integration

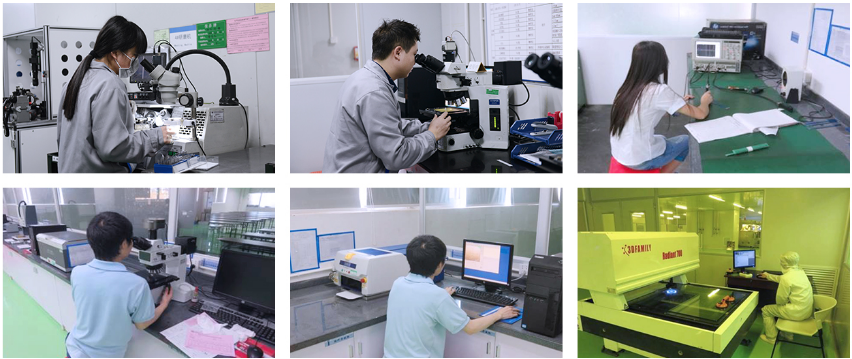

Compliance, Testing, and Quality Control

All industrial medical PCBs must pass regulatory and functional compliance tests, including:

Regulatory Certifications:

- ISO 13485: Medical device quality management

- IEC 60601: Safety and performance for medical electrical equipment

- FDA & CE Compliance: Mandatory for market access in U.S. and Europe

Testing Protocols:

- AOI (Automated Optical Inspection)

- ICT (In-Circuit Testing)

- Functional and thermal cycling tests

- X-ray inspection for BGA and hidden joints

Why Choose Wintech for Industrial Medical PCBs

Wintech stands out as a proven electronics manufacturing services (EMS) partner trusted by many Fortune 500 companies. They specialize in high-mix, low to mid volume production—ideal for the precise and diverse requirements of industrial medicine.

Wintech Core Advantages:

- 30+ years of experience in electronics and PCB production

- Custom solutions for high-complexity, high-precision layouts

- One-stop turnkey services from prototyping to full-scale production

- Certified cleanrooms and advanced testing labs

Service Portfolio:

- PCB Design & Layout

- PCB Manufacturing

- SMT & Through-Hole PCB Assembly

- Fast Turn Prototypes

- New Product Introduction (NPI)

- Plastic & Metal Housing Manufacturing

Summary Table

| Requirement | Description | Wintech Solution |

|---|---|---|

| Reliability & Longevity | Essential for continuous operation in critical systems | Precision manufacturing & ISO-certified quality control |

| Signal Integrity | Prevents data loss and distortion in medical imaging | High-speed design and impedance control |

| Material Selection | Thermal, chemical, and electrical properties are key | Supports FR-4, Polyimide, Ceramic, Rogers |

| Design Complexity | Multilayer, HDI, and miniaturized components | Expert high-difficulty and large-size board layout |

| Testing & Compliance | Ensures safety, reliability, and market access | Comprehensive AOI, ICT, functional testing, CE/FDA support |

| Assembly & Turnkey | Full product lifecycle from design to delivery | Quick turn prototyping, SMT, NPI, and enclosure production |